Oct . 13, 2024 05:17 Back to list

api wafer type butterfly valve

Exploring the API Wafer Type Butterfly Valve An Insight into Its Design and Applications

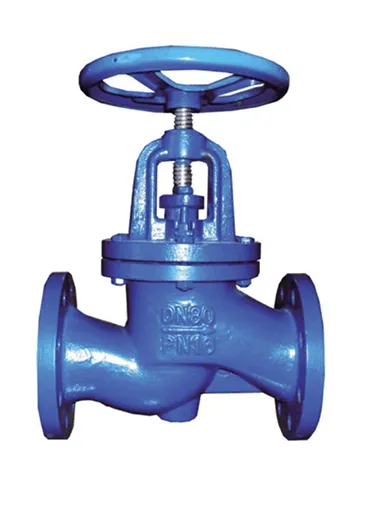

The API wafer type butterfly valve is an essential component in modern fluid control systems, enabling efficient regulation of flow within various industrial applications. This valve type is characterized by its unique design, which offers advantages in terms of space efficiency, weight, and performance compared to traditional valve designs. As industries continue to evolve, understanding the features of the API wafer type butterfly valve becomes increasingly important for engineers, designers, and operators alike.

Understanding the Structure

The wafer type butterfly valve features a disc that rotates around a central shaft, allowing it to either block or permit flow. This valve is fitted between two flanges in a piping system, which is what distinguishes it from other types of butterfly valves. The wafer design facilitates direct mounting onto the pipe without the need for substantial modifications. The compact and lightweight nature of wafer type butterfly valves makes them particularly appealing for applications where space is constrained.

The disc of the valve is typically positioned perpendicular to the flow when closed and parallel when opened. This design enables a tight seal when closed, minimizing leakage. Engineers often select materials such as stainless steel, ductile iron, or PVC for the valve body and disc, depending on the specific requirements of the fluid being controlled, including pressure, temperature, and corrosiveness.

Benefits of Wafer Type Butterfly Valves

One of the primary benefits of API wafer type butterfly valves is their efficiency in terms of space and weight. In applications where weight and footprint are critical, such as in chemical processing or oil and gas industries, these valves provide a perfect solution without compromising performance. Their design allows for quick installation and maintenance, which can significantly reduce downtime in industrial processes.

Another notable advantage is the cost-effectiveness of these valves. The manufacturing process is usually simpler and less expensive than other valve types, resulting in lower initial costs. Moreover, their operational efficiency can lead to lower long-term operational costs, as the energy required to open and close the valve is relatively low compared to other types.

api wafer type butterfly valve

Applications Across Industries

API wafer type butterfly valves find applications in a myriad of industries. In the water and wastewater sector, they are used for controlling the flow of water and ensuring efficient operation of treatment plants. Their ability to provide a reliable seal makes them ideal for applications where fluid leakage could have significant environmental implications.

In the oil and gas sector, these valves are invaluable for maintaining flow control in pipelines and processing plants. The robust construction and corrosion-resistant materials commonly used in these valves ensure longevity even in harsh conditions. Additionally, the food and beverage industry frequently uses wafer type butterfly valves due to their hygienic design and ease of cleaning, which is critical in maintaining sanitary conditions.

The Role of Standards

Adherence to industry standards is crucial when selecting butterfly valves for specific applications. API (American Petroleum Institute) standards provide guidelines for the design, testing, and materials used in the manufacturing of valves used in the petroleum and natural gas industries. Ensuring compliance with these standards not only guarantees the quality and reliability of the valve but also instills confidence among operators regarding safety and performance.

Conclusion

In summary, the API wafer type butterfly valve is an integral part of many modern fluid control systems, offering significant advantages in terms of design, functionality, and cost-efficiency. Its compact size, reliability, and versatility allow for application across a wide range of industries, from water treatment to oil and gas processing. As the demand for efficient fluid control solutions grows, the significance of understanding and utilizing API wafer type butterfly valves will continue to rise, paving the way for innovation and improved performance in fluid management systems. The selection of the right valve, based on application needs and adherence to relevant standards, plays a pivotal role in achieving operational success and maintaining system integrity.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025