Dec . 07, 2024 03:57 Back to list

Understanding the Function and Importance of Air Compressor Release Valves

Understanding the Air Compressor Release Valve

Air compressors are a staple in various industries and applications, providing vital compressed air used in tools, machinery, and processes. One critical component of an air compressor system is the release valve, also known as the pressure relief valve or safety valve. This valve plays an essential role in ensuring the safe and efficient operation of the compressor. In this article, we will explore the functionality, importance, and maintenance of air compressor release valves.

What is an Air Compressor Release Valve?

An air compressor release valve is a safety feature designed to prevent excessive pressure buildup in the compressor tank. When air is compressed, it generates significant pressure. Without a proper safety mechanism in place, this pressure could reach dangerous levels, potentially leading to equipment failure or even catastrophic accidents. The release valve automatically releases air if the pressure exceeds a predetermined threshold, ensuring the safety of both the equipment and the operator.

How Does It Work?

The release valve operates on a simple yet effective principle. It is typically set to open at a specific pressure level, known as the set pressure. When the pressure in the compressor tank exceeds this level, the valve opens to vent excess air, reducing the pressure back to a safe range. Once the pressure falls below the set level, the valve closes again, sealing the tank.

Many air compressors come equipped with an adjustable release valve, allowing users to set the desired pressure thresholds based on their operational needs. However, it is crucial to ensure that this adjustment is made according to manufacturer specifications to maintain safety.

Importance of the Release Valve

1. Safety Assurance The primary role of the release valve is to provide a failsafe mechanism to prevent excessive pressure buildup. This not only protects the compressor from damage but also ensures the safety of individuals working near the equipment.

2. Enhanced Equipment Longevity By regulating pressure levels, the release valve helps to minimize wear and tear on compressor components. This can lead to reduced maintenance costs and extended equipment life.

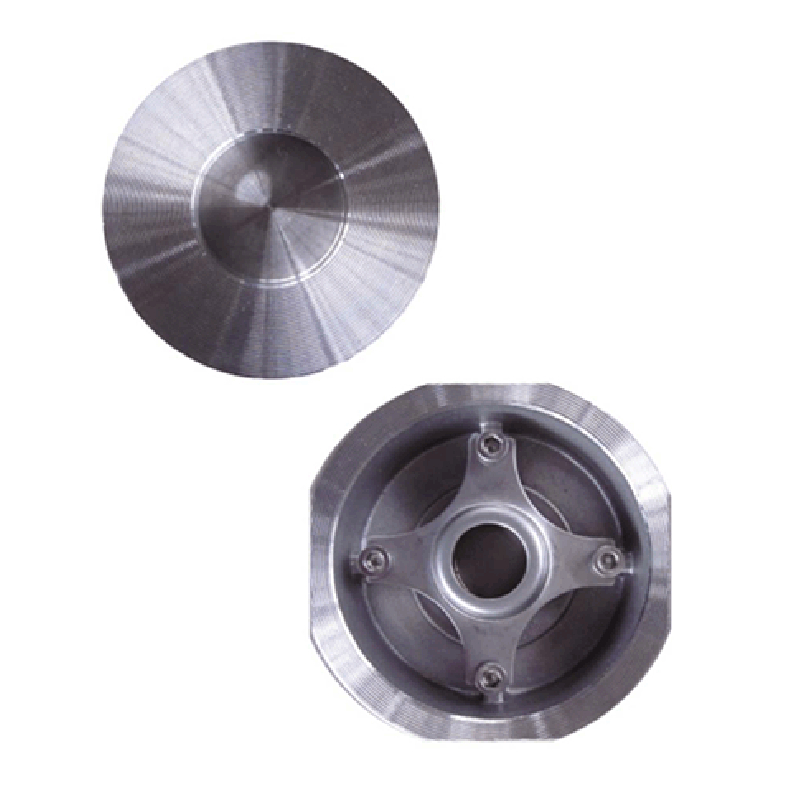

air compressor release valve

3. Consistency in Operation A properly functioning release valve ensures that the compressor operates within its design specifications, leading to consistent performance in air delivery. This is especially important in applications that require specific air pressures for optimal performance.

Maintenance of the Release Valve

To ensure the effective operation of the release valve, regular maintenance is essential. Here are a few tips

- Routine Inspections Periodically inspect the release valve for any signs of wear, corrosion, or malfunction. Look for leaks or buildup of debris around the valve, which could impede its functioning.

- Testing Pressure Settings It is advisable to test the pressure settings periodically to ensure that the valve opens and closes at the correct threshold. This can usually be done using a pressure gauge.

- Cleaning and Lubrication Keeping the valve clean and properly lubricated can help maintain its responsiveness. However, be cautious with lubricants, as the wrong type could cause operational issues.

- Professional Assistance If any irregularities are detected, or if you are unsure about the valve’s functionality, consulting with a professional technician is recommended. They can provide a thorough assessment and necessary repairs or replacements.

Conclusion

In conclusion, the air compressor release valve is a critical component that plays a pivotal role in the safety and efficiency of compressor operations. Understanding its function and importance can help users appreciate the need for regular maintenance and vigilance. By properly maintaining the release valve, operators can ensure a safe working environment, prolong the lifespan of their equipment, and maintain consistent performance in their air compression needs.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025