Jan . 21, 2025 05:26 Back to list

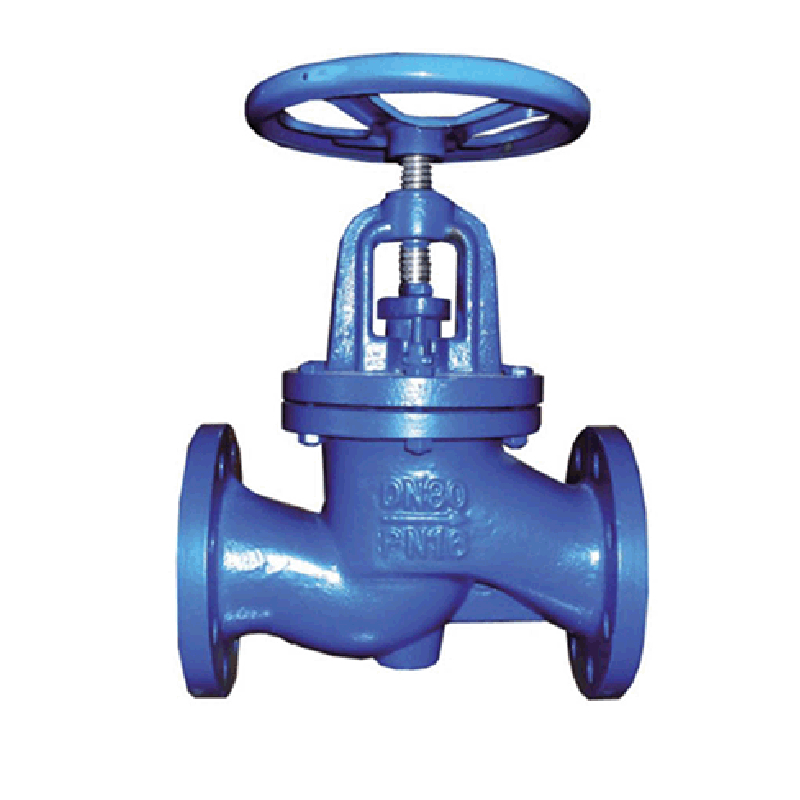

DIN Resilient Seat Gate Valve NRS

An actuated gate valve is a versatile and essential component in the realm of fluid control systems. Its ability to manage the flow of a wide range of fluids, from water to oil to gas, makes it indispensable in industries such as manufacturing, oil refining, water treatment, and chemical processing. This state-of-the-art fluid control miracle brings a perfect blend of convenience, efficiency, and reliability, changing how modern industries handle fluid transport.

Trustworthiness in actuated gate valve technology is built through the continuous development and adoption of cutting-edge innovations. As industries strive towards sustainability, manufacturers are designing valves to minimize leakage and improve energy efficiency, supporting global environmental goals. Enhanced through feedback from field operations and research advancements, these improvements help sustain customer confidence and promote the adoption of actuated valves across sectors. Installation and maintenance of actuated gate valves are designed for simplicity and efficiency. They are fitted into pipelines with standard connection mechanisms, allowing for seamless integration with existing infrastructures. Frequent inspections and timely actuator calibrations further extend the life cycle of the equipment, ensuring it operates at peak performance. Manufacturers often provide comprehensive training and support documentation, helping technicians and engineers understand the nuances of each valve model and how to troubleshoot any potential issues quickly. Safety, as an underlying benefit, remains paramount when employing actuated gate valves. Fail-safe designs are incorporated, where the valve defaults to an open or closed position in the event of a failure, minimizing risks associated with process control errors. Safety features such as lock-out mechanisms and position indicators further ensure that these valves align with stringent safety protocols required in critical applications. In conclusion, actuated gate valves present an elegant solution to the demands of modern fluid control systems, harmonizing technology with industrial requirements. By offering precise control, robustness, and an avenue for automation, they propel industries towards greater heights of efficiency and safety. As the industry continues to evolve, these valves will remain a vital component, consistently proving their worth and reaffirming their place at the forefront of fluid management solutions.

Trustworthiness in actuated gate valve technology is built through the continuous development and adoption of cutting-edge innovations. As industries strive towards sustainability, manufacturers are designing valves to minimize leakage and improve energy efficiency, supporting global environmental goals. Enhanced through feedback from field operations and research advancements, these improvements help sustain customer confidence and promote the adoption of actuated valves across sectors. Installation and maintenance of actuated gate valves are designed for simplicity and efficiency. They are fitted into pipelines with standard connection mechanisms, allowing for seamless integration with existing infrastructures. Frequent inspections and timely actuator calibrations further extend the life cycle of the equipment, ensuring it operates at peak performance. Manufacturers often provide comprehensive training and support documentation, helping technicians and engineers understand the nuances of each valve model and how to troubleshoot any potential issues quickly. Safety, as an underlying benefit, remains paramount when employing actuated gate valves. Fail-safe designs are incorporated, where the valve defaults to an open or closed position in the event of a failure, minimizing risks associated with process control errors. Safety features such as lock-out mechanisms and position indicators further ensure that these valves align with stringent safety protocols required in critical applications. In conclusion, actuated gate valves present an elegant solution to the demands of modern fluid control systems, harmonizing technology with industrial requirements. By offering precise control, robustness, and an avenue for automation, they propel industries towards greater heights of efficiency and safety. As the industry continues to evolve, these valves will remain a vital component, consistently proving their worth and reaffirming their place at the forefront of fluid management solutions.

Share

Prev:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025