Nov . 21, 2024 18:09 Back to list

8 inch check valve

Understanding the 8% 20 Inch Check Valve Importance and Applications

In various industrial applications, maintaining the correct flow of liquids and gases is crucial for operational efficiency and safety. Check valves play a significant role in this aspect, with the 8% 20 inch check valve emerging as a notable component in many systems. This article will explore the details, features, and applications of the 8% 20 inch check valve, providing a comprehensive understanding of its importance.

What is a Check Valve?

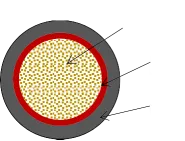

A check valve is a mechanical device that allows fluid to flow in one direction while preventing backflow. This is essential in systems where reverse flow can cause damage, contamination, or inefficiency. Check valves can be found in a variety of designs, such as swing check valves, lift check valves, and ball check valves. The 8% 20 inch check valve, as indicated by its dimensions, typically has a diameter of 20 inches, signifying it is designed for larger pipelines and systems.

Features of the 8% 20 Inch Check Valve

The designation 8% generally refers to the valve's flow capacity or its design to manage specific flow conditions. The 20-inch diameter signifies its application in larger systems, where robust materials and engineering design are required to withstand high pressures and volumes.

One of the primary features of the 8% 20 inch check valve is its durability. These valves are usually constructed from materials like stainless steel, ductile iron, or other sturdy alloys, making them suitable for various corrosive or high-pressure environments. They are engineered to ensure reliable performance over extended periods, minimizing the need for maintenance and replacements.

8 inch check valve

Moreover, the design of the valve plays a vital role in its efficiency. Many modern check valves are designed with streamlining in mind, reducing turbulence and energy loss during operation. This feature is particularly vital in large-scale industrial applications where flow efficiency can result in significant cost savings and enhanced productivity.

Applications

The 8% 20 inch check valve is widely used in industries such as water treatment, oil and gas, power generation, and chemical processing. In water treatment plants, for example, these valves help prevent the backflow of contaminated water, ensuring a clean and safe supply for consumers.

In the oil and gas sector, they are crucial in pipelines to prevent backflow that could lead to spills or leaks, significantly enhancing environmental safety. Similarly, in power generation, check valves manage coolant and steam flows to ensure that systems operate within safe parameters, maximizing efficiency and safety.

Additionally, chemical processing facilities use these valves to safeguard against hazardous material leaks, contributing to workplace safety and compliance with environmental regulations.

Conclusion

The 8% 20 inch check valve is a vital component in many industrial applications, providing a reliable solution for managing fluid flow and preventing backflow. Its robust design, coupled with its capacity to efficiently manage large volumes, makes it indispensable in a variety of sectors including water treatment, oil and gas, and chemical processing. As industries continue to evolve and demand more efficient and durable solutions, the role of check valves, particularly the 8% 20 inch variant, will undoubtedly grow, underscoring their importance in modern engineering practices. Understanding these valves is crucial for maintaining safe and efficient operations across many fields.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025