Aug . 28, 2024 11:16 Back to list

8 Inch Check Valve - Reliable Backflow Prevention Solutions

Understanding the 8-Inch Check Valve Essential Features and Applications

Check valves are critical components in various fluid systems, ensuring unidirectional flow and preventing backflow. Among them, the 8-inch check valve plays a significant role in industries ranging from water treatment to HVAC systems. In this article, we delve into the importance, features, and applications of the 8-inch check valve.

What is an 8-Inch Check Valve?

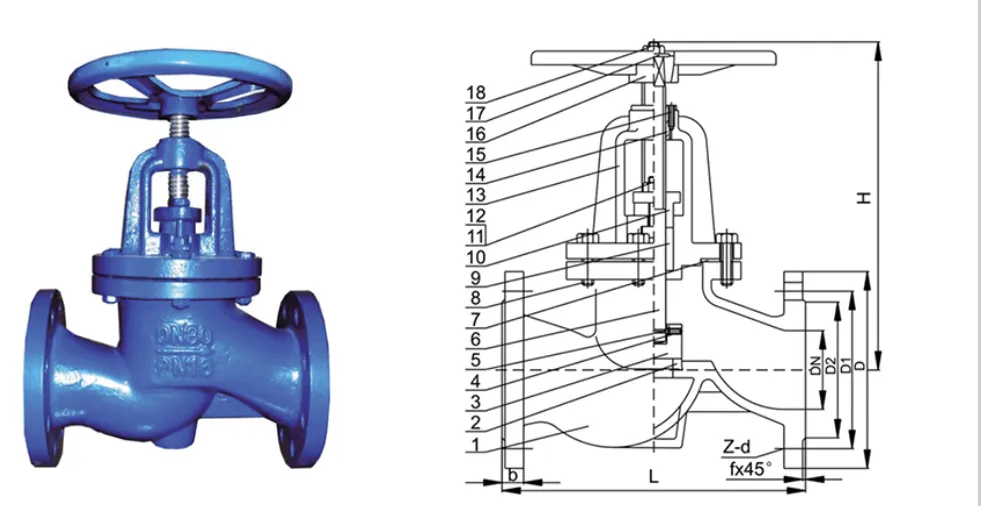

An 8-inch check valve is a type of valve designed to allow fluid to flow in one direction while preventing any reverse flow. The diameter, measured at 8 inches, indicates the size of the valve and its capacity to handle significant fluid volumes. These valves are typically constructed from durable materials such as stainless steel, PVC, or cast iron, designed to withstand high pressures and challenging environmental conditions.

Key Features

1. Unidirectional Flow The primary function of an 8-inch check valve is to ensure that fluids can only flow in one direction. This is crucial in preventing backflow, which can cause process contamination or system damage.

2. Pressure Rating Most 8-inch check valves are designed to operate under specific pressure ratings, which indicates the maximum pressure the valve can handle. It's essential for engineers to select a valve that aligns with the operational pressure of the system.

3. Seal Integrity Quality check valves maintain an effective seal to prevent leaks. The sealing mechanism, often including rubber or elastomeric materials, offers reliability and longevity.

4. Design Variations There are several design types of check valves, including swing check valves, lift check valves, and ball check valves. Each design has its advantages depending on the application, such as minimizing turbulence or ensuring swift closure.

8 inch check valve

Applications

The 8-inch check valve is versatile and finds applications across various sectors

- Water Treatment Facilities These valves are crucial in wastewater and drinking water systems, where they help protect pumps and other equipment from backflow.

- HVAC Systems In heating, ventilation, and air conditioning systems, 8-inch check valves regulate the flow of fluids, preventing return flow that could disrupt system efficiency.

- Industrial Processes Manufacturing plants often use these valves in piping systems to maintain consistent flow directions during processes.

- Wastewater Management In sewer systems, they play an essential role in preventing sewage from flowing back into treatment facilities.

Conclusion

In conclusion, the 8-inch check valve is a vital component in ensuring the safety and efficiency of fluid systems across various industries. Understanding its features and applications can help engineers and operators make informed decisions regarding system design and maintenance. With advances in materials and technology, check valves continue to evolve, providing even greater reliability and performance in demanding environments.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025