Nov . 09, 2024 09:49 Back to list

Understanding the Functionality and Importance of Actuated Valves in Modern Systems

The Role and Importance of Actuated Valves in Modern Industry

Actuated valves are essential components in various industrial processes, providing significant advantages in automation, efficiency, and safety. These valves are designed to control the flow of fluids within a system, utilizing an actuator – an electromechanical device – to automate the opening and closing of the valve. This automation capability has made actuated valves a crucial part of many sectors, including oil and gas, water treatment, pharmaceuticals, and chemical manufacturing.

Types of Actuated Valves

Actuated valves come in various types, each suited to different applications. Common types include ball valves, gate valves, globe valves, and butterfly valves. Ball valves are known for their durability and reliability in achieving a tight seal, making them ideal for on/off control in pipelines. Butterfly valves, on the other hand, are particularly effective in regulating flow, thanks to their quarter-turn operation, which allows for quick and efficient adjustment.

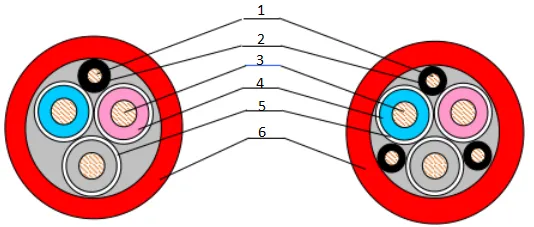

The actuators themselves can be electric, pneumatic, or hydraulic. Electric actuators are favored for their precision and ease of integration with control systems, while pneumatic actuators offer rapid action and are often used in environments where electric power is not feasible. Hydraulic actuators provide high torque and are suitable for extreme conditions, making them a preferred choice in heavy-duty applications.

Benefits of Using Actuated Valves

One of the primary advantages of actuated valves is their ability to enhance process automation. With advanced control systems, these valves can be operated remotely, allowing for real-time monitoring and adjustments without the need for manual intervention. This remote operation not only increases efficiency but also minimizes the risks associated with manual valve operation, especially in hazardous environments.

Moreover, actuated valves contribute to improved safety in industrial processes

. Automated systems can be programmed to respond quickly to changes in pressure or flow, mitigating the risk of accidents such as leaks or ruptures. Additionally, they are equipped with features such as position feedback, which provides operators with instant information about valve status, ensuring better control over the system.Another significant benefit is energy efficiency. By enabling precise control of flow, actuated valves can help optimize the use of energy resources. In industries where fluid flow directly impacts energy consumption, such as in HVAC systems or processing plants, the ability to modulate flow precisely can lead to substantial cost savings and reduced environmental impact.

actuated valve

Applications in Various Industries

In the oil and gas industry, actuated valves play a crucial role in controlling the flow of crude oil, natural gas, and processed products. They are used in drilling, pipeline transportation, and refining, ensuring that operations run smoothly and safely.

In the water treatment sector, these valves facilitate the management of water distribution systems, wastewater treatment plants, and industrial water processing. Their ability to handle different pressures and flow rates makes them invaluable in maintaining water quality and ensuring regulatory compliance.

The pharmaceutical industry also relies on actuated valves for precise control of fluid processes essential for drug manufacturing. The stringent requirements for cleanliness and accuracy in this sector make actuated valves a preferred choice, as they can be easily integrated into automated clean-in-place (CIP) systems, ensuring the safety and efficacy of pharmaceutical products.

Future Trends and Innovations

As technology advances, the future of actuated valves looks increasingly promising. Developments in IoT (Internet of Things) and smart automation are leading to more intelligent valve control systems. These systems can monitor performance, predict maintenance needs, and even analyze data to optimize operations further.

Moreover, the ongoing trend towards sustainability is driving innovations in actuated valve technology, focusing on energy efficiency and reduced environmental impact. Manufacturers are exploring new materials and designs that enhance durability while minimizing resource consumption during production and operation.

Conclusion

In conclusion, actuated valves are pivotal in modern industrial operations, providing automation, safety, and efficiency across various sectors. As industries continue to evolve and embrace smart technologies, the role of actuated valves will only grow in significance, ensuring that processes are not only efficient but also safe and environmentally responsible. As such, investing in reliable actuated valve systems is essential for any organization looking to thrive in today’s competitive and rapidly changing industrial landscape.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025