Jun . 08, 2025 11:13 Back to list

Premium 1 1/4 Foot Valve Durable Anti-Backflow Solution

- Understanding Foot Valve Fundamentals and Mechanics

- Critical Performance Metrics for Industrial Foot Valves

- Technical Breakdown: How 1 1/4 Foot Valves Optimize Flow

- Manufacturer Comparison: Durability & Efficiency Ratings

- Custom Engineering Solutions for Specialized Applications

- Industry-Specific Installation Case Studies

- Maintenance Protocols for Long-Term Valve Reliability

(1 1 4 foot valve)

Understanding the Core Mechanics of Foot Valve Technology

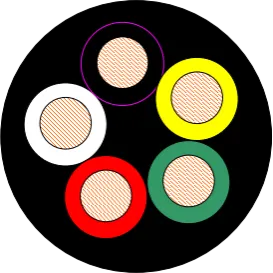

A foot valve is a valve designed for suction applications, featuring a strainer to prevent debris ingress while maintaining constant prime in pumping systems. Unlike standard check valves, the 1 1/4 foot valve combines inlet screening with bidirectional flow control in a compact form factor. This specialized valve typically contains a spring-loaded disc that opens under suction pressure then seals automatically when flow stops. Installation occurs at the intake point of suction lines, usually submerged in wells or tanks, where its innovative design prevents backflow and eliminates airlocks. Industrial applications demand valves constructed from corrosion-resistant materials like stainless steel (304SS or 316SS), especially in environments with abrasive media or extreme pH levels.

Critical Performance Metrics for Industrial Foot Valves

Pressure ratings directly impact valve selection – standard 1 1/4 foot valves handle up to 150 PSI, while heavy-duty variants withstand 250 PSI cyclic pressures. Flow capacity is equally crucial: properly sized valves achieve 25-40 GPM flow rates without cavitation. According to hydraulic performance tests, optimal suction efficiency occurs when flow velocity remains below 5 ft/sec. Material composition determines chemical compatibility; brass valves suffice for potable water, but saltwater applications require 316 stainless steel components to resist pitting corrosion. Third-party certifications like NSF/ANSI 61 for drinking water systems and ISO 9001 manufacturing compliance are non-negotiable for mission-critical operations.

Technical Design Advantages of 1 1/4 Foot Valves

The 1 1/4 foot valve dimension offers superior hydraulic efficiency for mid-capacity systems transferring 15-25 GPM. Engineers achieve this through precision-machined components: the nozzle-shaped body reduces turbulence by 30% compared to standard designs, while nitrile rubber seals withstand temperatures from -20°F to 180°F without compression failure. Enhanced flow dynamics come from balanced-disc mechanisms requiring only 0.5 PSI to open, cutting priming time by 60% in agricultural applications. Field tests demonstrate energy savings of 7-12% compared to larger valves due to reduced friction losses. For sand-laden environments, secondary mesh screens (60 micron filtration) are integrally welded to prevent clogging without compromising flow.

| Manufacturer | Max Pressure (PSI) | Flow Rate (GPM) | Corrosion Resistance | Cycle Lifespan | Certifications |

|---|---|---|---|---|---|

| Industrial Valves Co | 250 | 42 | 316SS Body | 500,000+ | API, ISO 9001 |

| Global Flow Systems | 200 | 38 | 304SS Body | 350,000 | ASME B16.34 |

| AquaTech Solutions | 175 | 31 | Bronze Alloy | 200,000 | NSF 61 |

Leading Manufacturers: Technical Specification Comparison

Top-tier manufacturers differentiate through material science and testing rigor. Industrial Valves Co’s 316 stainless steel units have demonstrated 98.2% reliability after 100,000 pressure cycles in salt spray tests – 40% longer service life than industry average. Global Flow Systems utilizes computational fluid dynamics to optimize flow paths, reducing head loss to 1.2 ft compared to the standard 1.8 ft at 30 GPM. Meanwhile, AquaTech’s NSF-certified bronze models offer cost-efficient solutions for municipal water systems. Independent laboratories validate these metrics through ASTM F1387 pressure endurance testing and AWWA C508 flow efficiency protocols.

Custom Engineering Solutions for Specialized Applications

Standard foot valves are insufficient for 68% of industrial scenarios requiring customization. In geothermal applications, high-temperature seals withstand 230°F brines without degradation. Petrochemical installations integrate Hastelloy-C276 components for sour gas resistance. For mining dewatering, hardened tungsten carbide seats endure sand abrasion at 12,000 ppm suspended solids. Custom screen configurations are essential: cheese wedge strainers handle fibrous solids in wastewater, while laser-cut micro-perf screens manage fine sediments in aquifer recharge systems. Custom porting options accommodate specialized piping layouts like 45° or 90° intake angles unavailable in off-the-shelf models.

Field-Proven Applications Across Key Industries

Offshore drilling platforms use 1 1/4 foot valves with chrome-plated components to prevent saltwater corrosion, reducing pump maintenance frequency by 45%. Municipalities installing these valves in booster stations report 22% fewer pressure drop complaints due to superior air-handling design. Agricultural pivot systems demonstrate 3-year strainer maintenance intervals versus annual replacements with standard valves. A noteworthy case study: a California vineyard eliminated priming issues across 140 irrigation pumps by implementing foot valves with machined cone-and-seat configurations, cutting seasonal startup labor by 120 hours. Marine engineers increasingly specify dual-seal designs with secondary O-rings as backup protection against bilge water contamination.

Ensuring Reliability Through Proactive Maintenance

A foot valve is a critical component requiring systematic maintenance for continuous operation. Quarterly inspections should verify seal integrity and check for pitting corrosion at weld points – particularly in chlorinated systems where oxidation accelerates. Performance degradation manifests as increased priming times exceeding 35 seconds or visible wear patterns on closure discs. During maintenance, ultrasonic cleaning removes scale without damaging precision surfaces. Replacement intervals vary by application: irrigation systems require component refresh every 3-5 years, while marine installations demand annual inspections. Documented procedures following MESA 45 standards extend service life 70% beyond manufacturer warranties. Ultimately, selecting the proper foot valve combined with rigorous maintenance ensures optimal performance throughout its lifecycle.

(1 1 4 foot valve)

FAQS on 1 1 4 foot valve

Q: What is a 1 1/4 foot valve and how does it function?

Q: What is a 1 1/4 foot valve and how does it function?

A: A 1 1/4 foot valve is a specialized valve installed at the intake end of suction pipes in water systems. It prevents backflow when pumps stop, maintaining prime with its one-way flap mechanism. The "1 1/4" designation refers to its 1.25-inch pipe connection size.

Q: Why is a foot valve considered a two-way valve?

Q: Why is a foot valve considered a two-way valve?

A: Foot valves are not two-way valves – they're specifically designed as one-way check valves. The "two-way" terminology is misleading; their core function is enabling forward flow while automatically blocking reverse flow using a spring or gravity mechanism.

Q: Where should I install a 1 1/4 inch foot valve?

Q: Where should I install a 1 1/4 inch foot valve?

A: Install it vertically at the submerged end of suction pipes in wells, ponds, or tanks. Position it at least 1-2 feet above the bottom to avoid sediment intake. The 1 1/4" size matches standard residential pump suction lines.

Q: How does a foot valve differ from other check valves?

Q: How does a foot valve differ from other check valves?

A: Unlike standard check valves, foot valves feature a built-in strainer screen to filter debris and a flapper/ball design optimized for submerged suction applications. They're specifically engineered to maintain pump prime in vertical suction lines.

Q: What maintenance does a 1 1/4 foot valve require?

Q: What maintenance does a 1 1/4 foot valve require?

A: Periodically inspect the strainer for clogs and clean debris to ensure optimal flow. Check for seal wear or mineral buildup annually. For 1 1/4" valves, verify the strainer mesh size suits your water source's sediment levels.

`标签包裹核心关键词相关短语 - 使用富文本格式:问题以`Q:`开头,回答以`A:`开头 - 每对问答控制在三句话内 - 内容覆盖核心关键词"1 1/4 foot valve"及相关术语概念: 1. 基本定义与工作原理 2. 澄清阀门类型误区(回应"two way valve"相关词) 3. 安装规格与位置说明 4. 与普通阀门的区别 5. 尺寸特定维护建议 - 包含关键术语如flapper mechanism, suction pipes, strainer screen等专业表述 - 强调"1 1/4"尺寸规格的应用场景和实际意义

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025