Nov . 03, 2024 12:41 Back to list

vnidirectional knife gate valve

Understanding Vnidirectional Knife Gate Valves

Knife gate valves are essential components within various industrial applications, especially in the handling of slurries, liquids, and gases. A specific subset, known as vnidirectional knife gate valves, has gained attention due to their unique design and functionality. These valves are primarily used in processes that require a reliable seal and efficient flow control, making them indispensable in industries such as wastewater treatment, mining, and power generation.

Design and Operation

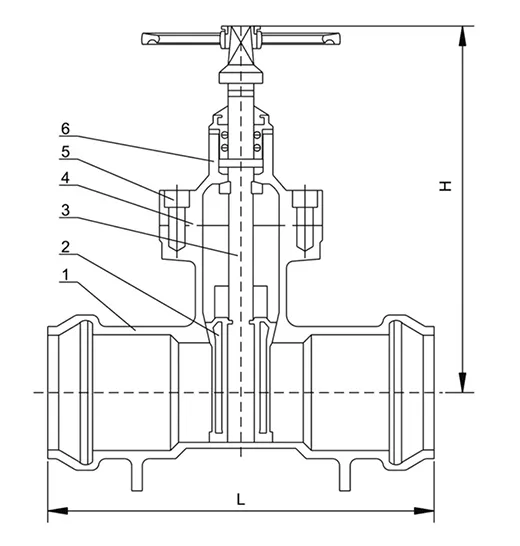

Vnidirectional knife gate valves feature a specially designed blade, or knife, that penetrates the flow stream to provide a positive shutoff. The blade's geometry allows it to cut through thick materials, like sludge or slurry, thereby ensuring a complete closure and minimizing leakage. Unlike traditional gate valves, the vnidirectional design implies that these valves are intended for flow in one direction. This characteristic is crucial in applications where backflow could lead to contamination or process inefficiencies.

The operation of a vnidirectional knife gate valve is straightforward. When the valve is in the open position, the knife blade is retracted, allowing materials to flow freely. When the valve is closed, the blade drops down, cutting off the flow tightly against the seating surface. This mechanism eliminates the risk of fluid seeping past the gate, which is especially important when handling aggressive or abrasive substances.

Advantages of Vnidirectional Knife Gate Valves

vnidirectional knife gate valve

One of the primary advantages of vnidirectional knife gate valves is their ability to handle heavy-duty applications. Their robust construction allows them to withstand high pressures and temperatures, making them suitable for harsh environments. Additionally, the design helps to reduce turbulence in the flow, thus minimizing wear and tear on both the valve and associated piping systems.

Another significant benefit is reduced maintenance. The knife-edge design cuts and seals effectively, reducing the chance of clogs and the need for frequent repairs. This reliability translates to less downtime, enhancing the overall efficiency of operations.

Applications

Vnidirectional knife gate valves are widely used in various sectors. In wastewater treatment facilities, they help manage sludge and other waste materials, ensuring efficient processing. In the mining industry, they are crucial for controlling the flow of slurries and preventing backflow, which could cause contamination or process inefficiencies. They are also employed in pulp and paper industries, chemical processing, and food and beverage applications, where hygiene and flow control are paramount.

Conclusion

In conclusion, vnidirectional knife gate valves represent a vital technology in industrial flow control. Their specialized design offers reliable performance in demanding applications, ensuring efficient management of materials and processes. As industries continue to evolve, the role of these innovative valves will likely expand, underscoring their importance in maintaining operational efficiency and safety. By investing in high-quality vnidirectional knife gate valves, companies can enhance their productivity while minimizing risks associated with fluid handling.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025