Dec . 19, 2024 19:42 Back to list

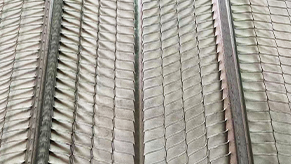

epdm lined butterfly valves

Understanding EPDM Lined Butterfly Valves Applications and Advantages

In industrial applications, valves play a crucial role in regulating the flow of fluids. Among the various types of valves available, butterfly valves are widely recognized for their simplicity, versatility, and cost-effectiveness. When enhanced with an Ethylene Propylene Diene Monomer (EPDM) lining, these valves become highly suitable for a range of demanding environments. This article delves into the characteristics, advantages, and applications of EPDM lined butterfly valves.

What are EPDM Lined Butterfly Valves?

Butterfly valves consist of a circular plate or disc that rotates around a central axis to open or close the flow of liquid or gas. The design allows for quick operation, making them particularly advantageous in systems that require frequent cycling. The EPDM lining refers to a protective layer made from a synthetic rubber compound known for its excellent resistance to heat, ozone, and various chemicals.

Advantages of EPDM Lined Butterfly Valves

1. Chemical Resistance One of the most significant advantages of EPDM is its exceptional chemical resistance. This makes EPDM lined butterfly valves ideal for applications involving corrosive fluids, such as chemicals in wastewater treatment plants, pharmaceuticals, and food processing industries.

2. Temperature Tolerance EPDM can withstand a wide range of temperatures, typically up to 150°C (302°F), depending on the specific formulation. This temperature resilience suits applications in industries where temperature fluctuations are common.

3. Ozone and Weather Resistance EPDM is highly resistant to ozone and ultraviolet (UV) light, ensuring longevity when used in outdoor applications. This makes it an excellent choice for valves exposed to harsh environmental conditions.

epdm lined butterfly valves

5. Cost-Effectiveness The straightforward design of butterfly valves, combined with the advantageous properties of EPDM, makes these valves a cost-effective solution in many industrial applications. Lower maintenance costs due to the durability of EPDM further contribute to their appeal.

Applications of EPDM Lined Butterfly Valves

EPDM lined butterfly valves find widespread applications across various industries

- Water and Wastewater Treatment In municipal water systems and wastewater treatment facilities, EPDM lined valves are used to manage the flow of water and sewage, effectively preventing leaks and ensuring safe operation.

- Chemical Processing Many chemical manufacturing processes involve hazardous or corrosive substances. EPDM lined butterfly valves serve as reliable flow control solutions in these environments, ensuring safety and efficiency.

- Food and Beverage Industry The food industry requires strict hygiene standards, making the non-toxic nature of EPDM an essential feature. These valves are utilized in applications for handling fluids, slurries, and other substances in the production of food and beverages.

- HVAC Systems EPDM lined butterfly valves are also prevalent in heating, ventilation, and air conditioning (HVAC) systems to control air and fluid flow while maintaining energy efficiency.

Conclusion

EPDM lined butterfly valves represent a significant advancement in valve technology, combining the efficient operation of butterfly valves with the superior properties of EPDM. Their capacity to withstand harsh conditions, coupled with their versatility across various applications, makes them an indispensable component in many industrial systems. When choosing valves for specific applications, decision-makers should consider the benefits of EPDM lined options to ensure optimal performance and reliability. As industries continue to evolve, the demand for such advanced valve solutions will likely grow, solidifying their role in modern engineering systems.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025