Oct . 11, 2024 23:33 Back to list

Understanding the Function and Benefits of DIN Swing Check Valves in Piping Systems

Understanding DIN Swing Check Valves

Swing check valves are essential components in various industrial applications, designed to prevent the backflow of fluid in a piping system. One of the most recognized standards for swing check valves is the Deutsches Institut für Normung (DIN) standard. This article explores the characteristics, operational principles, applications, and advantages of DIN swing check valves.

What is a DIN Swing Check Valve?

A swing check valve is a type of non-return valve that automatically prevents fluid from flowing backward in a piping system. It operates through a disc that swings on a hinge or pivot, allowing the fluid to flow in one direction while blocking reverse flow. The DIN designation indicates that the valve complies with specific German industrial standards for quality and performance, which are widely accepted globally.

Characteristics of DIN Swing Check Valves

DIN swing check valves possess several key characteristics that make them suitable for various applications

1. Material Construction Typically made from durable materials such as stainless steel, cast iron, or bronze, DIN swing check valves are designed to withstand high pressure and temperature conditions.

2. Size Range These valves are available in a range of sizes, usually from DN 15 (15mm) to DN 1200 (1200mm), making them adaptable to different pipeline systems.

3. Pressure Rating DIN swing check valves are manufactured to withstand various pressure ratings, commonly in line with PN 10, PN 16, and PN 25 specifications.

4. Design The design of the valve includes a hinged disc that allows for smooth flow in one direction. This mechanism ensures minimal pressure drop across the valve when the fluid is flowing, making them efficient for continuous service.

Operational Principles

The operation of a DIN swing check valve is straightforward yet effective. When fluid flows in the designated direction, the pressure lifts the disc, allowing for unobstructed flow. Upon cessation of flow or reversal, the weight of the disc and back pressure exerted by the fluid close the valve, preventing backflow. This simple yet efficient mechanism contributes to the valve's reliability in various applications.

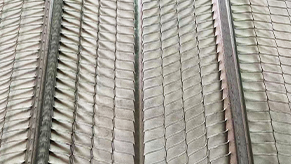

din swing check valve

Applications

DIN swing check valves are used in a wide range of applications, including

- Water Supply Systems Ensuring one-way flow in municipal water distribution and irrigation systems. - Sewage Treatment Management Preventing backflow in sewage and wastewater management systems. - Industrial Processes Employed in chemical processing, oil and gas pipelines, and power generation facilities where backflow could disrupt operations or lead to contamination. - Heating Systems Used in HVAC systems to maintain one-way flow in heating systems, ensuring efficient operation.

Advantages of DIN Swing Check Valves

The use of DIN swing check valves offers several advantages

1. Reliability Their simple design and robust construction contribute to a high level of reliability, reducing the chances of malfunction.

2. Low Pressure Drop The streamlined design allows for minimal resistance to flow, ensuring efficiency in fluid transport.

3. Ease of Maintenance With fewer moving parts compared to other valve types, swing check valves are relatively low-maintenance, contributing to longer service life.

4. Cost-Effectiveness Their efficiency and reliability can lead to lower operational costs, making them a cost-effective choice for many applications.

5. Standard Compliance Adhering to DIN standards ensures that consumers receive a product that meets rigorous quality and performance benchmarks.

Conclusion

DIN swing check valves are crucial components that ensure the efficient and safe transport of fluids in various industries. Their design, operational principles, and adherence to high standards make them highly reliable. Whether used in water supply systems, industrial applications, or heating systems, their role in preventing backflow is indispensable. As industries continue to evolve and demand more efficient solutions, DIN swing check valves remain a steadfast choice for engineers and system designers alike. Investing in quality valves not only enhances system performance but also contributes to overall safety and operational efficiency.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025