Dec . 20, 2024 21:34 Back to list

3 way globe valve

The 3-Way Globe Valve A Critical Component in Fluid Control Systems

A 3-way globe valve is a specialized type of valve that plays a crucial role in various fluid control applications. Known for its versatility and reliability, this valve type allows for the management of flow paths within a piping system, making it an essential component in industries ranging from oil and gas to water treatment and HVAC systems.

Design and Structure

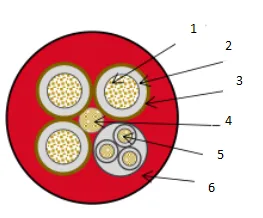

At its core, a 3-way globe valve consists of three ports and a globe-shaped body, which is the source of its name. The three ports include one inlet and two outlets, or in some configurations, one outlet and two inlets. This design enables the valve to perform two primary functions directing flow and mixing fluids. The valve's internal structure includes a moveable disc mounted on a stem, which opens or closes the flow path as it moves up or down within the valve body.

The globe valve shape provides a higher resistance to flow compared to other valve types, such as ball valves. However, this resistance is often an acceptable trade-off for the precise flow control it offers. The 3-way configuration further enhances its capability; it can facilitate a variety of operations, including diverting flow from one outlet to another or blending two separate streams into a single output.

Operating Mechanisms

There are different types of 3-way globe valves, classified by their operating mechanisms the mixing type and the diverting type. The mixing valve takes two separate inlet flows and combines them into one outlet, allowing for precise temperature or concentration control. In contrast, the diverting valve directs one inlet stream to one of the two outlets, allowing for versatile process control.

The actuation of a 3-way globe valve can be accomplished through various methods, including manual, pneumatic, hydraulic, or electric actuators. The choice of actuation depends on the specific application requirements, such as response time, control accuracy, and the physical environment in which the valve operates.

3 way globe valve

Applications

The applications for 3-way globe valves are diverse. In the oil and gas industry, they are used to control the flow of hydrocarbons, facilitating the transfer of fluids between different parts of the system. In chemical processing, they regulate the mixing of different reagents, ensuring that the final product maintains the desired properties. Additionally, in water treatment facilities, these valves help manage the distribution of treated water to various points in the distribution system.

Furthermore, HVAC systems frequently utilize 3-way globe valves for temperature control. By mixing hot and cold water to achieve the desired output temperature, these valves play a key role in energy efficiency and comfort in building environments.

Advantages

The advantages of 3-way globe valves are manifold. First and foremost, they provide excellent flow regulation, allowing for precise adjustments to flow rates and pressures. Their robust design also ensures durability, making them suitable for high-pressure and high-temperature applications. Moreover, their ability to mix or divert flows enhances process control, leading to improved efficiency and safety in various applications.

However, it is important to consider the potential downsides of using a 3-way globe valve. Their higher resistance to flow can lead to pressure drops within the system, which may necessitate the use of larger pumps or increased energy consumption. Additionally, the maintenance of globe valves can sometimes be more complex than that of simpler valve designs, requiring careful attention to the internal components over time.

Conclusion

In summary, the 3-way globe valve is an indispensable tool in the arsenal of fluid control solutions. Its ability to effectively manage flow paths makes it highly valuable in a multitude of industries. From oil and gas to HVAC, the versatility and reliability of this valve ensure that processes can run smoothly and efficiently. As fluid dynamics continue to play an essential role in industrial operations, the significance of the 3-way globe valve will only grow, solidifying its position as a critical component in modern engineering.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025