नोव्हेंबर . 29, 2024 20:58 Back to list

Enhancing Performance in Challenging Environments and Demanding Applications

Understanding Severe Service A Critical Perspective

In the realm of industrial operations, the term severe service holds significant importance. It refers to conditions under which equipment and components operate under extreme environments and challenging circumstances. These conditions can include high temperatures, intense pressures, corrosive media, and abrasive particles. The understanding and management of severe service applications are crucial because they directly impact the reliability, safety, and efficiency of industrial processes.

Severe service environments are commonplace in industries such as oil and gas exploration, chemical processing, power generation, and mining. For instance, in the oil and gas sector, extraction processes often involve high-pressure pipelines that transport hydrocarbons under extreme conditions. A failure in this context not only results in financial losses but can also pose significant risks to environmental safety and human life. This reality underscores the need for specialized equipment that can withstand such harsh conditions.

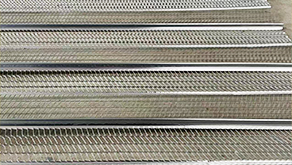

A critical element of addressing severe service challenges involves the careful selection of materials and equipment design. For example, metals used in severe service environments must exhibit high resistance to corrosion and abrasion. Advanced alloys and coatings are developed to enhance the longevity and performance of components such as valves, pumps, and fittings. Additionally, engineering practices such as redundancy, thoughtful design, and regular maintenance schedules are implemented to ensure that the equipment can handle operational stresses without failure.

severe service

Moreover, it is essential for companies operating in severe service environments to adopt a proactive approach to maintenance. Predictive maintenance strategies utilizing advanced diagnostic tools can help monitor equipment health and anticipate failures before they occur. This not only minimizes downtime but also extends the life of the equipment. Investing in training for personnel to ensure they are knowledgeable about severe service challenges is equally as important, as skilled workers can identify and mitigate issues more effectively.

The advancement of technology has introduced innovative solutions to improve performance in severe service conditions. For instance, automated monitoring systems can provide real-time data on pressure, temperature, and other critical parameters, allowing for informed decision-making. Furthermore, specialized designs that accommodate thermal expansion and contraction can help manage the stresses imposed by high-temperature applications.

As industries increasingly navigate the complexities of severe service environments, collaboration among engineers, manufacturers, and operators becomes essential. Sharing best practices, designing standardized components for severe conditions, and developing industry-wide safety guidelines can lead to improved operational efficiencies and enhanced safety.

In conclusion, severe service environments pose unique challenges that necessitate a comprehensive understanding of material science, engineering principles, and proactive operational strategies. By embracing cutting-edge technologies, adopting rigorous maintenance practices, and fostering a culture of collaboration, companies can effectively tackle the multifaceted issues associated with severe service. This not only results in improved reliability and reduced costs but also contributes to the overall safety and sustainability of industrial operations. As the demands of modern industry grow, continuous innovation in addressing the challenges of severe service will remain paramount.

Share

-

Y Strainers: Protecting Your Pipes with PrecisionNewsAug.27,2025

-

Wafer Type Butterfly Valves: Reliable Flow Control SolutionsNewsAug.27,2025

-

Wafer Type Butterfly Valves: Essential Components for Efficient Flow ControlNewsAug.27,2025

-

Reliable Flow Control with High-Quality Check ValvesNewsAug.27,2025

-

Reliable Flow Control with Gate ValvesNewsAug.27,2025

-

Innovative Check Valves for Reliable Flow ControlNewsAug.27,2025