11-р сар . 22, 2024 08:10 Back to list

swing check valve factory

Understanding Swing Check Valve Factory Processes

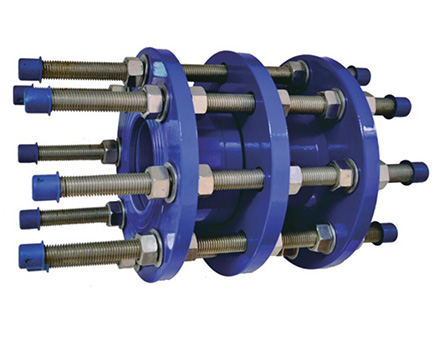

Swing check valves are critical components in various industrial applications, allowing fluid to flow in one direction while preventing backflow. Their design is relatively simple, featuring a disc that swings on a hinge, allowing it to open when fluid flows in the intended direction and to close when backflow occurs. The manufacturing process of swing check valves is essential to ensure their reliability and efficiency in operation. This article delves into the intricacies of swing check valve factories, elaborating on the manufacturing processes, materials, quality control, and their importance in industrial settings.

Manufacturing Process

The manufacturing process of swing check valves typically begins with material selection. Common materials include cast iron, stainless steel, and bronze, depending on the application and environmental conditions the valve must withstand. Once the material is chosen, it is subjected to various processes, including casting, machining, and assembly.

In the casting phase, molten metal is poured into molds to form the valve body. This is a critical step as it determines the structural integrity of the valve. After casting, the components undergo machining, where excess material is removed, ensuring that the surfaces are smooth and precise. The disc, hinge, and seat are particularly important, as any imperfections can lead to leaks or valve malfunctions.

Following machining, the components are cleaned and prepared for assembly. During this phase, precision is crucial. Each component, from the disc to the hinge pin, must be assembled with care to ensure that the valve functions correctly. A well-assembled swing check valve allows smooth operation and prevents backflow effectively.

swing check valve factory

Quality Control

Quality control is a vital aspect of the manufacturing process in a swing check valve factory. Manufacturers conduct rigorous testing to ensure that every valve meets industry standards and specifications. Pressure testing is commonly carried out to check for any leaks. Additionally, the functionality of the valve is tested to ensure it opens and closes smoothly under varying pressures.

Advanced technologies like ultrasonic testing and X-ray inspection may also be employed to detect internal flaws that are not visible to the naked eye. By ensuring that each valve is subjected to stringent quality checks, the manufacturer can guarantee reliability and longevity in real-world applications.

Importance in Industrial Applications

Swing check valves serve a crucial role in various sectors, including water treatment, oil and gas, and chemical processing. Their ability to prevent backflow protects pumps, compressors, and other equipment, thereby enhancing system efficiency and reducing maintenance costs. Moreover, swing check valves are designed to handle high flow rates and pressures, making them suitable for demanding environments.

In conclusion, swing check valve factories play a pivotal role in the manufacturing of these essential components. By focusing on quality materials, rigorous manufacturing processes, and comprehensive quality control, these factories ensure the production of reliable valves that meet industry demands. As industries continue to evolve, the significance of high-quality swing check valves remains paramount in maintaining operational integrity and enhancing overall process efficiency.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025