12-р сар . 16, 2024 03:24 Back to list

lined butterfly valve

Understanding Lined Butterfly Valves Design, Applications, and Benefits

Lined butterfly valves have emerged as essential components in various industrial applications, particularly in processes involving corrosive substances, slurries, or materials that could otherwise wear down standard valve materials. These valves combine the functionality of a typical butterfly valve with an added layer of protection—often a special lining material that enhances their performance and lifespan.

What are Lined Butterfly Valves?

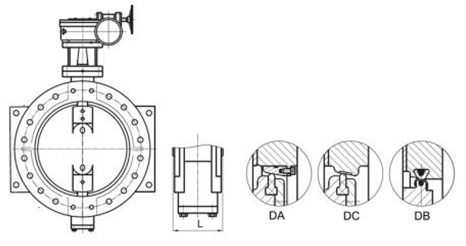

A lined butterfly valve operates on the same principle as a standard butterfly valve, which consists of a rotating disk that either allows or restricts flow through a pipeline. The key difference lies in the lining material that coats the valve body and, in some designs, the disk itself. Common lining materials include PTFE (Polytetrafluoroethylene), PFA (Perfluoroalkoxy), and other corrosion-resistant plastics. These linings provide substantial protection against chemical attack, abrasion, and high temperatures, making lined butterfly valves highly effective in a variety of demanding environments.

Design Features

The design of lined butterfly valves is critical to their functionality. The valve’s body is typically made from a robust material such as cast iron, steel, or plastic, which provides structural integrity. The lining is applied to the interior surfaces of the valve, ensuring that it comes into direct contact with the fluid being controlled. Manufacturers often utilize advanced techniques to ensure that the lining adheres properly to the valve surface, which minimizes the risk of delamination or failure.

In addition to their protective lining, lined butterfly valves are equipped with various features that enhance their usability. For example, they can be fitted with pneumatic, electric, or manual actuators to allow for precise control over flow rates. Some designs may also include features such as seat designs that ensure tight sealing when the valve is closed, thereby preventing leaks and ensuring continued system efficiency.

Applications

Lined butterfly valves find their applications in multiple industries, including

1. Chemical Processing Due to their resistance to corrosive chemicals, these valves are extensively used in the chemical industry for the handling of acids, alkalis, and solvents.

3. Mining and Mineral Processing The presence of abrasive materials in mining processes necessitates the use of valves that can withstand high levels of wear, making lined butterfly valves an ideal choice.

lined butterfly valve

4. Water and Wastewater Treatment These valves are utilized in various applications within water treatment facilities, particularly for controlling flow rates of chemicals used in the treatment process.

5. Food and Beverage In food processing, the hygiene and non-reactive nature of lined butterfly valves make them suitable for handling food products and beverage materials.

Advantages

The benefits of lined butterfly valves are numerous

- Corrosion Resistance The lining provides excellent protection against corrosive environments, extending the life of the valve significantly.

- Reduced Maintenance Costs Due to their durability, lined butterfly valves require less frequent replacements and repairs, lowering operational costs.

- Improved Flow Control The designs allow for quick opening and closing, providing enhanced flow control and reducing the risk of cavitation.

- Versatility Lined butterfly valves can be adjusted or customized for a variety of pressure and temperature conditions, providing flexibility across applications.

- Seamless Integration With multiple connection types, they can be easily integrated into existing systems, promoting ease of installation and operation.

Conclusion

In conclusion, lined butterfly valves are critical components that enhance the efficiency and reliability of various industrial processes. Their robust design, combined with corrosion-resistant linings, makes them indispensable in environments where traditional valves may fail. Engineers and operators must consider the specific requirements of their applications to select the right valve type, allowing them to fully leverage the benefits that lined butterfly valves offer. With the continued evolution of materials and technologies, the future for lined butterfly valves looks promising, ensuring their place in modern industry for years to come.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025