3-р сар . 06, 2025 11:23 Back to list

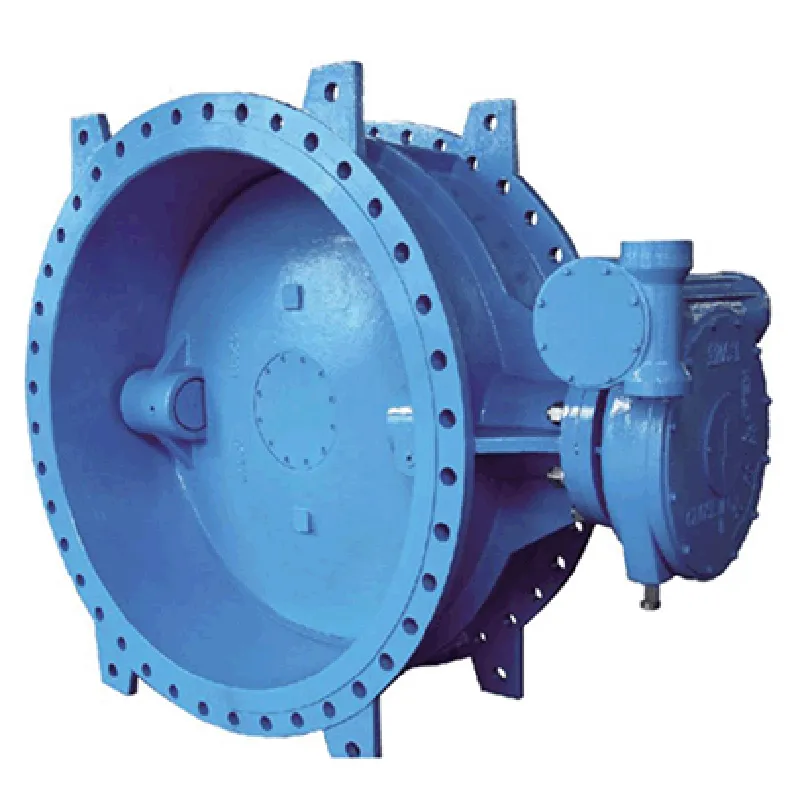

industrial check valve

Industrial check valves are indispensable components in numerous sectors ranging from oil and gas to water treatment, ensuring the efficient and safe flow of fluids within a system. Constructed to permit fluid flow in only one direction, these valves prevent backflow which can result in operational inefficiencies or even damage to systems. A comprehensive understanding of the functionality, types, and key considerations when selecting a check valve contributes significantly to industrial operations and asset longevity.

4. Dual Plate Check Valves Known for their efficiency and compactness, dual plate check valves feature two plates that open and close based on flow pressure. Their lightweight structure reduces piping stress, beneficial in large-scale industrial applications. Selection Criteria for Optimal Performance To harness the full benefits of industrial check valves, careful consideration of several factors is paramount. Compatibility with system pressure, temperature, and medium is crucial, alongside material selection to prevent corrosion and wear. Furthermore, understanding the flow characteristics and velocity is essential to avoid damaging surges or erratic flow patterns. The Valve's Role in Sustainable Practices Beyond their basic functionality, industrial check valves contribute significantly to energy efficiency and sustainability in operations. By preventing unnecessary flow reversals, they minimize energy consumption required to repressurize systems, thereby reducing operational costs and environmental impact. Authoritative Insights and Best Practices When selecting and maintaining check valves, consulting with manufacturers and industry experts is advisable. Manufacturers provide valuable technical support, ensuring that chosen valves meet rigorous industry standards and certifications for safety and efficiency. Regular inspections and maintenance, guided by expert advice, enhance the valve's performance and lifespan. A Symbol of Trust and Quality Over the years, brands specializing in industrial check valves have established a reputation for reliability and precision engineering. Companies such as Crane, Velan, and Cameron have become synonymous with quality, ensuring their products adhere to stringent specifications that meet or exceed industry expectations. In conclusion, industrial check valves, though often overlooked, are integral components of fluid flow systems across industries. As stewards of one-directional flow, they uphold system integrity, operational efficiency, and environmental considerations. Understanding their diverse types, functional mechanisms, and selection criteria enhances not only system performance but also aligns operations with sustainable industrial practices. The trust placed in renowned manufacturers further underscores their pivotal role in modern industry.

4. Dual Plate Check Valves Known for their efficiency and compactness, dual plate check valves feature two plates that open and close based on flow pressure. Their lightweight structure reduces piping stress, beneficial in large-scale industrial applications. Selection Criteria for Optimal Performance To harness the full benefits of industrial check valves, careful consideration of several factors is paramount. Compatibility with system pressure, temperature, and medium is crucial, alongside material selection to prevent corrosion and wear. Furthermore, understanding the flow characteristics and velocity is essential to avoid damaging surges or erratic flow patterns. The Valve's Role in Sustainable Practices Beyond their basic functionality, industrial check valves contribute significantly to energy efficiency and sustainability in operations. By preventing unnecessary flow reversals, they minimize energy consumption required to repressurize systems, thereby reducing operational costs and environmental impact. Authoritative Insights and Best Practices When selecting and maintaining check valves, consulting with manufacturers and industry experts is advisable. Manufacturers provide valuable technical support, ensuring that chosen valves meet rigorous industry standards and certifications for safety and efficiency. Regular inspections and maintenance, guided by expert advice, enhance the valve's performance and lifespan. A Symbol of Trust and Quality Over the years, brands specializing in industrial check valves have established a reputation for reliability and precision engineering. Companies such as Crane, Velan, and Cameron have become synonymous with quality, ensuring their products adhere to stringent specifications that meet or exceed industry expectations. In conclusion, industrial check valves, though often overlooked, are integral components of fluid flow systems across industries. As stewards of one-directional flow, they uphold system integrity, operational efficiency, and environmental considerations. Understanding their diverse types, functional mechanisms, and selection criteria enhances not only system performance but also aligns operations with sustainable industrial practices. The trust placed in renowned manufacturers further underscores their pivotal role in modern industry.

Share

Prev:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025