9-р сар . 23, 2024 02:48 Back to list

8 inch check valve

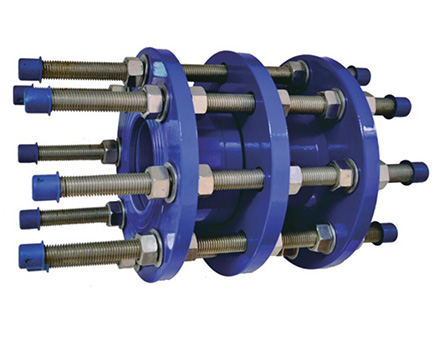

Understanding the 8-Inch Check Valve A Vital Component in Fluid Systems

In the world of fluid management and industrial applications, the efficiency and safety of systems rely heavily on the components used within them. One such critical component is the check valve, particularly the 8-inch check valve, which plays a significant role in regulating fluid flow and preventing backflow in pipelines.

Understanding the 8-Inch Check Valve A Vital Component in Fluid Systems

The 8-inch check valve is specifically designed for applications requiring a larger flow capacity. With a diameter of eight inches, it accommodates significant volumes of fluid, making it suitable for various industrial environments, including water treatment plants, wastewater management facilities, and chemical processing plants. Its robust construction ensures that it withstands the rigors of high-pressure applications, providing reliability and longevity.

8 inch check valve

When choosing an 8-inch check valve, several factors must be considered. The material of construction is one of the most critical aspects, as it influences the valve's compatibility with the fluids being transported. Common materials include cast iron, stainless steel, and plastic, each offering distinct advantages depending on the application. For instance, stainless steel is often preferred in corrosive environments, while plastic may be suitable for less aggressive fluids.

In addition to material considerations, the design of the check valve is essential for optimal performance. There are various designs available, such as swinging check valves and spring-loaded check valves. Each design has its benefits; for instance, swinging check valves are typically suitable for lower flow velocities, while spring-loaded valves provide tighter seals and can handle higher velocities.

Ultimately, the 8-inch check valve is a vital component in maintaining the efficiency and safety of fluid transport systems. Its ability to prevent backflow contributes to the overall integrity of industrial processes, ensuring that systems operate smoothly without interruptions or damage. As industries continue to evolve and demand more reliable fluid management solutions, the significance of the check valve, particularly in the 8-inch size, will only increase. Therefore, understanding its features, applications, and considerations is crucial for engineers and facility managers alike.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025