ജനു . 13, 2025 16:03 Back to list

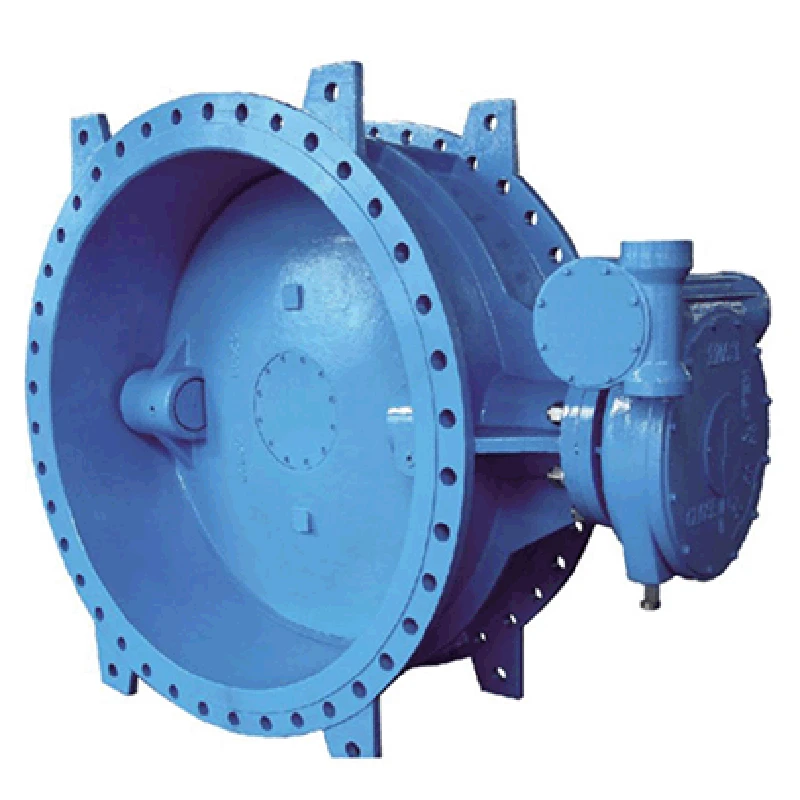

Wafer Type Butterfly Valve

Choosing the Best Cast Steel Valve for Your Industrial Needs

Ensuring Trustworthiness Through Quality Assurance Trust in cast steel valve performance is fortified through stringent quality assurance processes. Industry leaders perform comprehensive testing, including hydrostatic testing, non-destructive examination, and material analysis. Such tests confirm the integrity of the valve under pressure and operational conditions. Partnering with reputable manufacturers not only ensures the quality of the valves but also offers continued support through after-sales service. This ongoing support is critical in industrial environments where downtime translates to financial loss. Navigating the Selection Process Selecting the perfect cast steel valve involves a detailed understanding of the working environment. Consideration must be given to factors such as corrosive elements and abrasion, which may demand specific coatings or treatments like epoxy or zinc plating to extend valve life. Equally vital is ensuring compatibility with existing systems to prevent operational bottlenecks or inefficiencies. To craft a comprehensive procurement strategy, consulting with industry experts is recommended. These professionals can provide invaluable insights into the latest advancements in valve technology and solutions tailored to unique industry challenges. Embracing the latest trends, such as smart valves with remote monitoring capabilities, can further enhance system reliability and efficiency. Conclusion In the intricate realm of industrial operations, cast steel valves play a pivotal role in ensuring smooth functioning and safety. By emphasizing criteria such as material quality, standards compliance, and tailored suitability to specific applications, industries can significantly enhance their operational reliability. Investing in high-quality cast steel valves translates to long-term savings and safety, establishing a foundation of trust and expertise in industrial processes. With the right approach, your enterprise can harness the full potential of these integral components, driving success and innovation in the ever-evolving industrial landscape.

Ensuring Trustworthiness Through Quality Assurance Trust in cast steel valve performance is fortified through stringent quality assurance processes. Industry leaders perform comprehensive testing, including hydrostatic testing, non-destructive examination, and material analysis. Such tests confirm the integrity of the valve under pressure and operational conditions. Partnering with reputable manufacturers not only ensures the quality of the valves but also offers continued support through after-sales service. This ongoing support is critical in industrial environments where downtime translates to financial loss. Navigating the Selection Process Selecting the perfect cast steel valve involves a detailed understanding of the working environment. Consideration must be given to factors such as corrosive elements and abrasion, which may demand specific coatings or treatments like epoxy or zinc plating to extend valve life. Equally vital is ensuring compatibility with existing systems to prevent operational bottlenecks or inefficiencies. To craft a comprehensive procurement strategy, consulting with industry experts is recommended. These professionals can provide invaluable insights into the latest advancements in valve technology and solutions tailored to unique industry challenges. Embracing the latest trends, such as smart valves with remote monitoring capabilities, can further enhance system reliability and efficiency. Conclusion In the intricate realm of industrial operations, cast steel valves play a pivotal role in ensuring smooth functioning and safety. By emphasizing criteria such as material quality, standards compliance, and tailored suitability to specific applications, industries can significantly enhance their operational reliability. Investing in high-quality cast steel valves translates to long-term savings and safety, establishing a foundation of trust and expertise in industrial processes. With the right approach, your enterprise can harness the full potential of these integral components, driving success and innovation in the ever-evolving industrial landscape.

Share

Next:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025