നവം . 01, 2024 00:55 Back to list

Understanding Wafer Type Butterfly Valves for Efficient Fluid Control Applications

Understanding Wafer Type Butterfly Valves A Comprehensive Overview

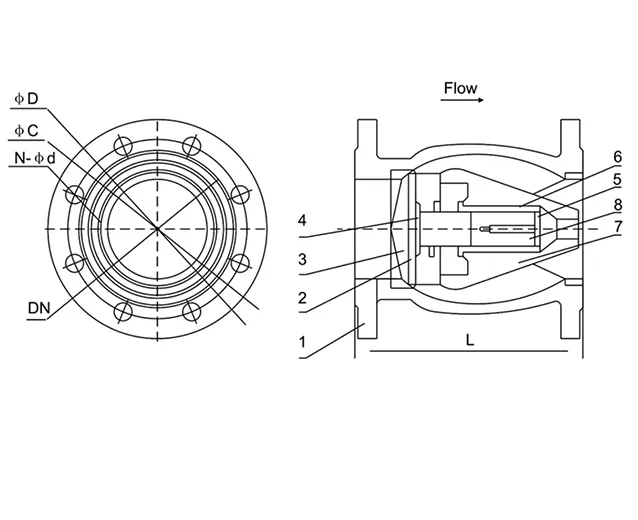

Wafer type butterfly valves are increasingly becoming a preferred choice in various industrial applications due to their unique design, compactness, and reliable functionality. Unlike traditional valves, wafer type butterfly valves have a disc that rotates on a shaft, which is positioned at the center of the valve body. This mechanism allows for quick and efficient modulation of fluid flow, making them ideal for environments where space and time are critical.

One of the defining features of wafer type butterfly valves is their design. These valves are generally lightweight and compact, which makes installation easier, particularly in tight or space-constrained areas. The wafer design often allows the valve to be sandwiched between two flanges, optimizing the connections with minimal bolting required. This not only speeds up the installation process but also reduces the overall footprint of the piping system.

Made from durable materials such as stainless steel, cast iron, and plastic, wafer type butterfly valves can handle a wide range of temperature and pressure conditions. Their construction enables them to resist corrosion and wear, ensuring longevity even in challenging environments. This robustness is essential in industries such as water treatment, chemical processing, and HVAC, where valves are subjected to harsh conditions.

wafer type butterfly valve

Another advantage of wafer type butterfly valves is their operational efficiency. The quarter-turn operation allows for rapid opening and closing, making them ideal for applications that require swift control of flow. Additionally, the design minimizes pressure drop across the valve, contributing to energy efficiency in fluid transport systems. This means that industries can save on energy costs while ensuring optimal performance.

Maintenance of wafer type butterfly valves is also relatively simple. The absence of intricate internal components reduces the likelihood of mechanical failure, and in the case of wear, servicing or replacing the valve can often be done without significant downtime. Regular inspection and basic maintenance can extend the lifespan of the valves significantly.

In conclusion, wafer type butterfly valves represent a practical and efficient solution for controlling fluid flow in various industrial settings. Their compact design, robustness, and operational efficiency make them ideal for many applications, from municipal water systems to advanced chemical processing plants. As industries continue to seek ways to optimize performance while minimizing costs, the popularity of wafer type butterfly valves is expected to grow, solidifying their place in modern engineering solutions.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025