ഫെബ്രു . 13, 2025 18:35 Back to list

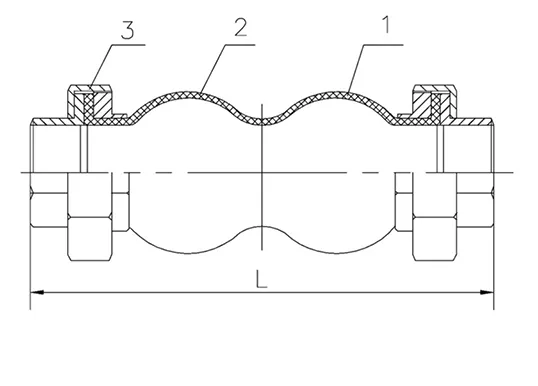

Wafer Type Butterfly Valve

Wafer style butterfly valves have become a cornerstone in modern industrial fluid management systems due to their compact design, ease of installation, and reliable performance. Their growing popularity can be attributed to their unique combination of economic efficiency and operational versatility, making them invaluable in a multitude of industrial applications. This article delves into the experiences with wafer style butterfly valves, underlining their professional expertise, authoritativeness, and trustworthiness.

Operational experiences with wafer style butterfly valves further reinforce their reputation for reliability and efficiency. Users often highlight the ease of maintenance as a significant advantage, which translates into reduced downtime and operational costs. Unlike their bulkier counterparts, wafer style butterfly valves require minimal effort to inspect and service, primarily since many can be maintained in-line without the need for complete disassembly. A significant aspect that adds to the valve's trustworthiness is their economic advantage over other valve types. The streamlined production process and use of less material make wafer style butterfly valves more cost-effective without compromising performance. This affordability is particularly beneficial for large-scale projects or systems with numerous valves where cost efficiency is paramount. Optimal selection and installation of these valves are critical to enhancing their lifespan and performance. Expertise in valve sizing and application-specific requirements is essential for achieving maximum efficacy. It's advisable for procurement and engineering teams to work closely with valve experts to ensure the compatibility of valve materials and design with the intended use case, considering factors such as flow rate, pressure, and chemical exposure. In conclusion, wafer style butterfly valves represent an ideal blend of economy, efficiency, and reliability. Their professional design and performance capabilities align with industry demands for sustainable and robust flow control solutions. Manufacturers and industry experts continue to innovate, further enhancing the reliability and applicability of wafer style butterfly valves, thereby assuring their relevance and indispensability in the future of industrial fluid management.

Operational experiences with wafer style butterfly valves further reinforce their reputation for reliability and efficiency. Users often highlight the ease of maintenance as a significant advantage, which translates into reduced downtime and operational costs. Unlike their bulkier counterparts, wafer style butterfly valves require minimal effort to inspect and service, primarily since many can be maintained in-line without the need for complete disassembly. A significant aspect that adds to the valve's trustworthiness is their economic advantage over other valve types. The streamlined production process and use of less material make wafer style butterfly valves more cost-effective without compromising performance. This affordability is particularly beneficial for large-scale projects or systems with numerous valves where cost efficiency is paramount. Optimal selection and installation of these valves are critical to enhancing their lifespan and performance. Expertise in valve sizing and application-specific requirements is essential for achieving maximum efficacy. It's advisable for procurement and engineering teams to work closely with valve experts to ensure the compatibility of valve materials and design with the intended use case, considering factors such as flow rate, pressure, and chemical exposure. In conclusion, wafer style butterfly valves represent an ideal blend of economy, efficiency, and reliability. Their professional design and performance capabilities align with industry demands for sustainable and robust flow control solutions. Manufacturers and industry experts continue to innovate, further enhancing the reliability and applicability of wafer style butterfly valves, thereby assuring their relevance and indispensability in the future of industrial fluid management.

Share

Next:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025