ജൂണ് . 10, 2025 08:42 Back to list

High-Quality Knife Valve PVC Reliable PVC Knife Gate Valve Manufacturers Sewer Knife Gate Valve Solutions

The Ultimate Guide to Knife Valve PVC: Unleashing Precision in Flow Control

Ever had a flow control system fail when you needed it the most? Leakage, corrosion, timely repairs… sound familiar? Over 35% of industrial pipeline failures are due to poor valve choices. Your system’s life and efficiency rest on the humble knife valve PVC. Imagine cutting downtime by half and slashing maintenance costs—without complex installation.

Today, let’s dive into the world of knife valve PVC, understand leading PVC knife gate valve manufacturers, and explore how the right solutions, such as sewer knife gate valve models, can transform your business. Ready to boost efficiency? Let's go!

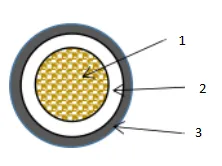

(knife valve pvc)

Why Knife Valve PVC Outshines Traditional Valves

PVC knife gate valves are designed for one thing—unmatched precision. Unlike ordinary steel or iron valves, a knife valve PVC provides a tighter shutoff, takes less effort to operate, and resists the most aggressive chemicals.

Need specs? Here’s a quick breakdown:

| Specification | Knife Valve PVC | Metal Gate Valve |

|---|---|---|

| Media Compatibility | Excellent (acids, bases, water, slurries) | Good (but prone to corrosion) |

| Operating Pressure | Up to 150 PSI | Up to 200 PSI |

| Maintenance | Minimal | Regular lubrication |

| Weight/Durability | Lightweight/High corrosion resistance | Heavy/Can rust |

This data tells you why industries (like water treatment and mining) trust PVC knife gate valves. They make operations seamless whether you’re handling clean water, sewage, or chemicals.

Choosing the Right PVC Knife Gate Valve Manufacturer

With so many options, who can you trust? Top PVC knife gate valve manufacturers stand out by offering:

- ISO 9001 certifications

- In-house testing labs

- Custom engineering

- Extensive after-sales support

The best manufacturers don’t just sell a valve. They help you select the right material, width, and actuation type. Sewer knife gate valve models, for example, often need extra seals or specific design features for sludge and waste applications.

Here’s how the top three U.S. manufacturers stack up:

| Manufacturer | Fast Shipping | Custom Options | Warranty |

|---|---|---|---|

| Flow-Master Inc. | ✔ | ✔ | 5 Years |

| ValvePro Solutions | ✔ | ✖ | 3 Years |

| PureValve Technologies | ✖ | ✔ | 5 Years |

Looking for someone who goes beyond the catalog? Flow-Master Inc. leads with tailored, rugged solutions. You get custom valve sizing and fast US shipping—every time.

Unlocking the Power of Custom Knife Valve PVC Solutions

Off-the-shelf not cutting it? For critical projects, you want a custom solution. Leading PVC knife gate valve manufacturers provide made-to-order valves with:

- Sophisticated actuators (manual, pneumatic, electric)

- True union ends for easy maintenance

- Special seals for high-abrasion or high-temperature applications

- Sizes from 2 inches up to 24 inches

Customers in municipal wastewater and food processing see drastic improvements—longer equipment life, fewer clogs, and no more midnight emergency calls.

| Parameter | Standard PVC Knife Gate Valve | Customized Sewer Knife Gate Valve |

|---|---|---|

| Operating Temp | 32 – 140°F | -10 – 212°F |

| Seal Type | EPDM | Viton/PTFE |

| End Connection | Socket/Flange | Flange/Custom |

Want maximum uptime? Demand a solution that matches your needs—not the manufacturer’s shelf.

Real Application Cases: Knife Valve PVC in Action

Still wondering where and why you should use the knife valve PVC? Let’s check some real numbers.

Case 1: Municipal Wastewater Plant (Ohio, 2022)

Facility replaced iron valves with custom sewer knife gate valve models from Flow-Master. Results? 48% reduction in maintenance costs in 12 months. Zero emergency shutdowns.

Case 2: Chemical Factory (Louisiana, 2023)

Switched to reinforced PVC knife gate valves on brine lines. Improved chemical resistance led to a 36% decrease in valve-related leaks—measured by factory incident logs.

Case 3: Bulk Food Processing Plant (California, 2021)

Used FDA-approved knife valve PVC with custom actuation. Annual savings: $18,000 on labor and valve replacements. Clean-in-place just got easier.

These aren’t just numbers. They are proof. The knife valve PVC isn’t a commodity—it’s a strategic investment.

Ready to Take Control? Choose a Trusted Knife Valve PVC Manufacturer Today

Let’s face it—your system deserves better. Outdated and rusty valves hurt your bottom line. Modern knife valve PVC products deliver precision, a tighter seal, and years of durability with almost no maintenance.

Whether you need standard models or a custom sewer knife gate valve engineered to spec, partnering with leading PVC knife gate valve manufacturers is your fast track to peace of mind. Why wait for another breakdown?

Bring the future to your flow control systems—choose Flow-Master Inc. as your partner. With over 30 years of industry experience, US-based engineering, and 24/7 support, our experts give you the edge. Don’t settle for less. Request a custom quote now, and experience the difference true innovation brings!

FAQs About Knife Valve PVC

Q1: What is a knife valve PVC and where is it used?

A knife valve PVC is a type of gate valve made from polyvinyl chloride plastic. It’s commonly used for flow control in water treatment, wastewater, chemical processing, and food plants. Its lightweight, corrosion-resistant body makes it a top choice for both clean and aggressive media.

Q2: Why choose a PVC knife gate valve over metal options?

PVC knife gate valves offer superior corrosion resistance, are lighter to install, and require less maintenance. They won’t rust, making them ideal for chemicals and sewage applications.

Q3: What should I look for in PVC knife gate valve manufacturers?

Always choose manufacturers with strong certifications, in-house testing, and the ability to customize valves. Look for fast delivery, technical expertise, and great after-sales service.

Q4: What makes a sewer knife gate valve different?

Sewer knife gate valves often have reinforced seals and special designs to handle abrasive sludge, solids, or corrosive sewage. They’re made for harsh, continuous operation.

Q5: How long does a knife valve PVC last?

With proper selection, a quality knife valve PVC can last 10-15 years—or longer—especially in non-pressurized or mildly corrosive environments.

Q6: Can I use a knife valve PVC for industrial chemicals?

Absolutely—if specified with the right seals and grade, PVC is highly chemical-resistant and outperforms metals in corrosive media.

Q7: How do I order a custom PVC knife gate valve?

Just reach out to your preferred manufacturer, such as Flow-Master Inc. Provide your line size, pressure, media, and temperature requirements. Their engineers handle the rest!

(knife valve pvc)

FAQS on knife valve pvc

Q: What is a knife valve PVC used for?

A: A knife valve PVC is typically used to control the flow of liquids, slurries, and solids in pipelines. Its sharp-edged gate can cut through flow materials, making it ideal for tough applications. This valve is commonly used in water treatment and industrial processes.Q: Who are reputable PVC knife gate valve manufacturers?

A: Several reputable manufacturers include manufacturers like Orbinox, DeZURIK, and Arita. It's best to compare specifications and certifications to ensure product quality. Always source from companies with strong industry reputations.Q: How does a knife valve PVC differ from standard PVC valves?

A: Knife valve PVC features a gate that slides through tough media, unlike standard ball or butterfly valves. This design helps handle thick liquids and solid particles efficiently. The unique knife-like gate sets it apart for difficult applications.Q: Can a sewer knife gate valve be used for wastewater applications?

A: Yes, a sewer knife gate valve is ideal for wastewater applications. It easily handles sludge and solid-bearing fluids in sewer lines. Its robust construction resists corrosion and clogging in harsh environments.Q: How do you maintain a knife valve PVC?

A: Regularly inspect for leaks and buildup around the gate area. Clean the valve and lubricate moving parts as recommended by the manufacturer. Prompt maintenance ensures reliable operation and long service life.Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025