മാര് . 05, 2025 06:19 Back to list

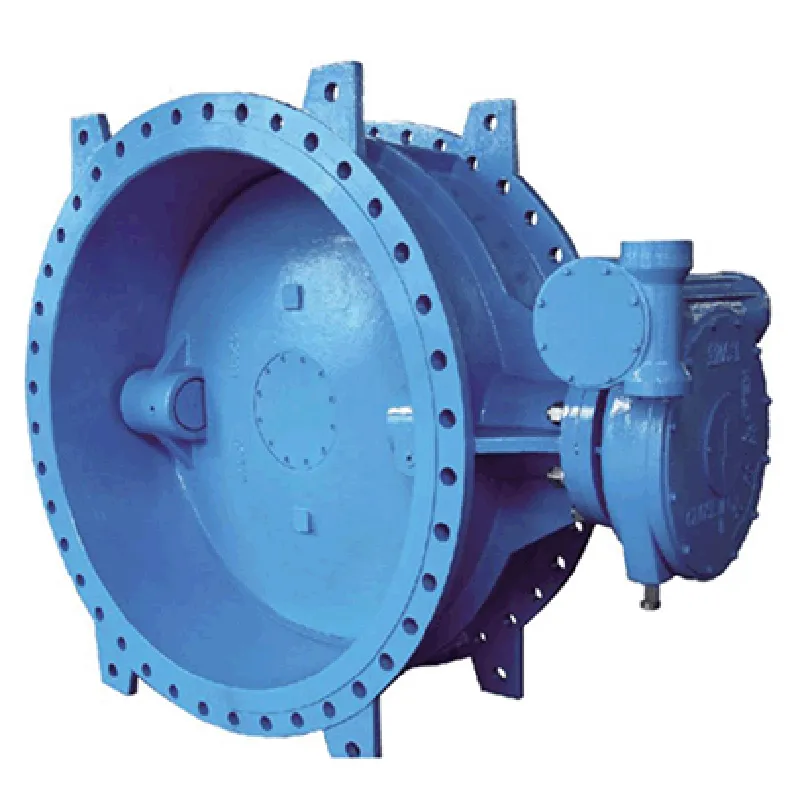

DIN Swing Check Valve

Industrial swing check valves are essential components in various industrial applications, playing a critical role in managing fluid dynamics and ensuring efficient operation within piping systems. When selecting the right swing check valve for a specific industry application, several factors must be considered to guarantee optimal performance, reliability, and longevity.

The authoritativeness of a swing check valve is often reflected in its design specifications and functionality. Valves from reputable manufacturers adhere to stringent industry standards and certifications, which is a testament to their reliability and quality. For industries where safety and reliability are of paramount importance, working with valves that meet or exceed these standards is non-negotiable. This authoritativeness assures users that the valve will function as intended under various operating conditions, reducing the risk of system failures, maintenance issues, or unplanned downtime. A reliable manufacturer's credentials often reflect years of research, field testing, and engineering refinements, which translate to the product’s trustworthiness. Trustworthiness in Installation and Maintenance The installation and maintenance of industrial swing check valves require a keen understanding of both the mechanical aspects and the operational parameters of the valve itself. Trustworthiness in this area means relying on professionals who can ensure proper installation and provide regular maintenance services to prolong the life of the valve and maintain system efficiency. Installing a swing check valve correctly is crucial for its performance. Improper installation could lead to leaks, inefficient operations, or even catastrophic failure in high-pressure systems. Meanwhile, routine maintenance, including regular inspections and cleaning, helps in early detection of any wear and tear, preventing costly breakdowns and ensuring continuous operation. In Conclusion Industrial swing check valves are indispensable components in many sectors, from petrochemical plants to water treatment facilities. Their simple yet effective design helps in maintaining the integrity and efficiency of fluid control systems. An in-depth understanding of the valve's functionalities, combined with expert selection of materials and authoritative design, contributes to its effectiveness and trustworthiness in industrial applications. For businesses looking to enhance their system’s performance, investing in expert advice for the right swing check valve ensures not only operational efficiency but also long-term cost savings and risk management. The role of expertise, trust, and authority cannot be understated in ensuring these valves meet the requisite safety and performance standards, which ultimately protects both the equipment and the processes they serve.

The authoritativeness of a swing check valve is often reflected in its design specifications and functionality. Valves from reputable manufacturers adhere to stringent industry standards and certifications, which is a testament to their reliability and quality. For industries where safety and reliability are of paramount importance, working with valves that meet or exceed these standards is non-negotiable. This authoritativeness assures users that the valve will function as intended under various operating conditions, reducing the risk of system failures, maintenance issues, or unplanned downtime. A reliable manufacturer's credentials often reflect years of research, field testing, and engineering refinements, which translate to the product’s trustworthiness. Trustworthiness in Installation and Maintenance The installation and maintenance of industrial swing check valves require a keen understanding of both the mechanical aspects and the operational parameters of the valve itself. Trustworthiness in this area means relying on professionals who can ensure proper installation and provide regular maintenance services to prolong the life of the valve and maintain system efficiency. Installing a swing check valve correctly is crucial for its performance. Improper installation could lead to leaks, inefficient operations, or even catastrophic failure in high-pressure systems. Meanwhile, routine maintenance, including regular inspections and cleaning, helps in early detection of any wear and tear, preventing costly breakdowns and ensuring continuous operation. In Conclusion Industrial swing check valves are indispensable components in many sectors, from petrochemical plants to water treatment facilities. Their simple yet effective design helps in maintaining the integrity and efficiency of fluid control systems. An in-depth understanding of the valve's functionalities, combined with expert selection of materials and authoritative design, contributes to its effectiveness and trustworthiness in industrial applications. For businesses looking to enhance their system’s performance, investing in expert advice for the right swing check valve ensures not only operational efficiency but also long-term cost savings and risk management. The role of expertise, trust, and authority cannot be understated in ensuring these valves meet the requisite safety and performance standards, which ultimately protects both the equipment and the processes they serve.

Share

Prev:

Next:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025