ഡിസം . 16, 2024 09:40 Back to list

Understanding Gate Valves and Their Operating Principles in Fluid Control Systems

Understanding Gate Valves The OSY (Outside Screw and Yoke) Design

Gate valves are pivotal in controlling the flow of fluids in various industrial applications. Among the different designs available, the Outside Screw and Yoke (OSY) gate valve is particularly noteworthy. This article aims to delve into the features, advantages, applications, and maintenance of OSY gate valves, illustrating why they are a preferred choice in many sectors.

What is an OSY Gate Valve?

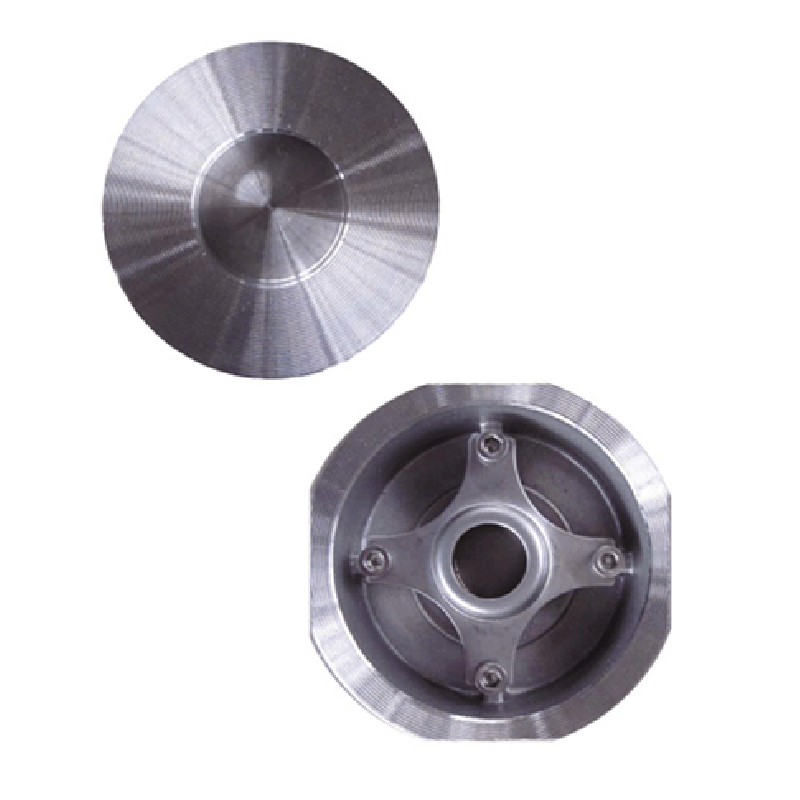

An OSY gate valve is characterized by its screw mechanism being located outside the valve body. The yoke structure supports the stem and the actuator, providing a mechanical advantage during operation. The primary function of an OSY gate valve is to allow or prevent the flow of fluid through a pipeline by raising or lowering a wedge-shaped gate. This type of valve is predominantly used in applications where the minimal flow restriction and a straight through passage are essential for the operational efficiency.

Key Features of OSY Gate Valves

1. Construction OSY gate valves are typically constructed from materials such as cast iron, ductile iron, stainless steel, or bronze, depending on the application and environmental conditions. This ensures durability and resistance to corrosion and wear.

2. Design The design of an OSY gate valve allows for direct visibility of the valve position, making it easier for operators to determine whether the valve is fully open or closed. The external screw mechanism also provides a more straightforward method for manual operation, requiring less effort to turn the valve.

3. Fluid Compatibility OSY gate valves can handle various fluids, including water, oil, and gas, making them versatile for multiple applications.

4. Sealing Mechanism The sealing mechanism in OSY valves involves the gate coming into contact with the valve seat, providing a tight seal when closed. This prevents leakage and ensures that the media flowing through the pipeline is contained effectively.

Advantages of OSY Gate Valves

1. Low Pressure Drop When open, OSY gate valves offer minimal resistance to flow, leading to a low-pressure drop across the valve. This is crucial in applications where maintaining pressure levels is critical for system performance.

2. Full Bore Passage The full-bore design allows for unrestricted flow, which is particularly advantageous in systems such as fire protection, where high flow rates are necessary.

3. Ease of Maintenance The external stem and yoke design simplify the maintenance process as they allow for easy access to the internal components without the need to remove the valve from the pipeline.

gate valve osy

4. Reliability OSY gate valves are known for their reliability and longevity. With proper maintenance, they can operate efficiently for many years, reducing the need for frequent replacements.

Applications of OSY Gate Valves

OSY gate valves are commonly used in a variety of industries, including

- Water Supply and Treatment These valves are essential in municipal water systems for controlling water distribution and managing pressure in pipelines. - Fire Protection Systems In fire suppression systems, OSY gate valves help control the flow of water to sprinkler systems and hydrants, ensuring an adequate supply of water during emergencies.

- Oil and Gas Industries They are widely used in the oil and gas sector for shutting off flow and allowing or preventing the delivery of crude oil and natural gas.

- Chemical Processing OSY valves can handle corrosive substances, making them suitable for industries requiring reliable shut-off in their processing operations.

Maintenance of OSY Gate Valves

To ensure the optimal performance and longevity of OSY gate valves, regular maintenance is crucial. This includes

- Routine Inspection Regularly checking for signs of wear or corrosion can help identify potential issues before they escalate.

- Lubrication Keeping the stem and threads lubricated can prevent seizing and facilitate smooth operation.

- Testing Periodically testing the valve under its operational conditions ensures that it functions correctly and meets safety standards.

Conclusion

In summary, OSY gate valves play a significant role in managing fluid flow across various applications. With their robust design, low-pressure drop, and ease of maintenance, they stand out as a reliable choice for industries striving for efficiency and safety. Understanding the characteristics and best practices related to OSY gate valves is vital for engineers and operators alike, ensuring that these critical components work effectively in their respective systems.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025