നവം . 15, 2024 00:39 Back to list

double eccentric butterfly valve

The Double Eccentric Butterfly Valve An Overview

The double eccentric butterfly valve, often referred to as the double offset butterfly valve, is a sophisticated mechanism designed to regulate the flow of fluids in various industrial applications. Unlike traditional butterfly valves, the double eccentric design offers enhanced performance and improved flow characteristics, making it a popular choice in sectors such as water treatment, oil and gas, and HVAC systems.

Design Features

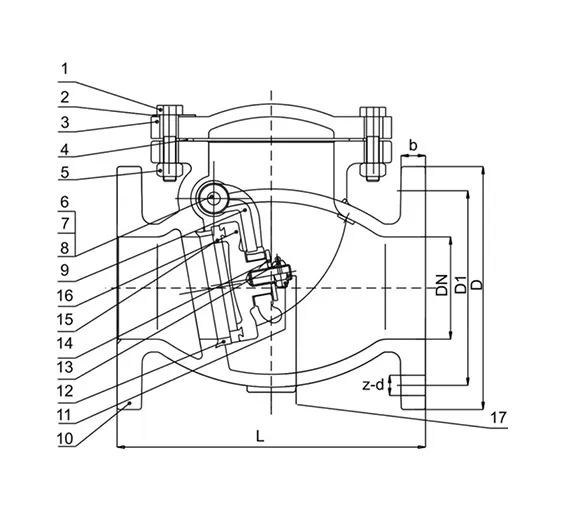

The primary distinction of the double eccentric butterfly valve lies in its unique design. The term double eccentric refers to the positioning of the valve shaft. In a typical butterfly valve, the shaft is centered within the disc, which means that the disc’s pivot point aligns with the center of the valve body. In contrast, the double eccentric model has two offsets one for the shaft and another where the shaft exits the valve body. This configuration allows the disc to move more freely, reducing the wear and tear associated with friction.

The key components of the valve include the disc, the valve body, the stem (or shaft), and the actuator. The disc, usually made from durable materials such as stainless steel or ductile iron, plays a crucial role in controlling fluid flow. When the actuator turns the stem, the disc rotates into or out of the flow path, allowing or blocking fluid passage. The valve body houses these components, designed to withstand high pressures and harsh environmental conditions.

Advantages of Double Eccentric Butterfly Valves

1. Reduced Friction The unique design minimizes contact between the disc and the valve sealing surfaces. This reduction in friction results in less wear, translating into a longer operational lifespan and decreased maintenance costs.

2. Better Flow Characteristics The flow through a double eccentric butterfly valve is more streamlined compared to traditional designs. Its ability to avoid turbulence means it can handle a wider range of flow conditions, providing stable performance even with varying system pressures.

double eccentric butterfly valve

3. High Performance in Different Media These valves can accommodate a variety of fluids, including liquids and gases, making them versatile for different applications. They are particularly effective in systems dealing with slurries and other challenging media.

4. Ease of Operation Double eccentric butterfly valves can be operated manually or automated through electric or pneumatic actuators. This flexibility allows for easy integration into remote and automated systems, enhancing operational efficiency.

5. Compact Size Compared to other valve types, the double eccentric butterfly valve is relatively compact. Its design saves space in piping systems, making it suitable for installations with spatial constraints.

Applications

These valves are widely employed in multiple sectors. In water and wastewater treatment plants, they are used for regulating flow and controlling pressure. In the oil and gas industry, they manage the transport of oil and natural gas under varying conditions. Additionally, HVAC systems utilize double eccentric butterfly valves to regulate airflow, contributing to energy efficiency in large buildings and industrial facilities.

Conclusion

In summary, the double eccentric butterfly valve stands out as a highly efficient and reliable choice for fluid control across various industries. Its innovative design reduces wear, enhances flow characteristics, and offers flexibility in operation, making it a favorable option for engineers and operators alike. As industries continue to evolve, the demand for sophisticated and efficient control mechanisms like the double eccentric butterfly valve will only grow, shaping the future of fluid handling solutions.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025