നവം . 30, 2024 18:38 Back to list

Understanding the Importance of Control Valves in Industrial Applications

Understanding Control Valves An Essential Component in Fluid Dynamics

Control valves play a critical role in various industries, including oil and gas, water treatment, and chemical manufacturing. These devices regulate the flow of fluid in a system by varying the size of the flow passage as directed by a controller. By adjusting the fluid flow and pressure, control valves ensure that processes run smoothly and efficiently, minimizing waste and ensuring safety.

How Control Valves Work

A control valve operates based on a simple principle it opens or closes to alter the flow of liquid or gas. The fundamental components of a control valve include the valve body, actuator, and control system. The valve body contains the flow passage, while the actuator adjusts the valve's position. The actuator can be either pneumatic, electric, or hydraulic and is controlled by a signal from the control system.

The process begins when the controller receives feedback from field instruments, such as flow meters or pressure sensors. This feedback indicates whether the fluid flow matches the desired setpoint. If a discrepancy is detected, the controller sends a signal to the actuator, prompting it to adjust the valve's position accordingly. This continuous feedback loop enables the control valve to maintain the desired flow rate or pressure, ensuring effective process control.

Types of Control Valves

Control valves come in various types, each suited for different applications. The most common types include

1. Globe Valves Known for their good throttling capability, globe valves feature a linear motion that makes them ideal for regulating flow.

2. Ball Valves These valves use a spherical disc to control flow. Ball valves offer rapid opening and closing capabilities but are not suited for throttling due to their binary operation.

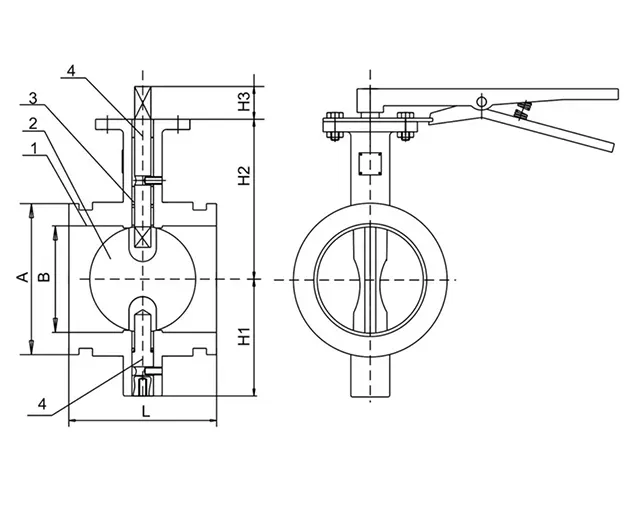

3. Butterfly Valves Featuring a rotating disc, butterfly valves are lightweight and compact. They are often used in applications where space is limited.

4. Gate Valves While primarily designed for on/off purposes, gate valves can also be used in flow control applications. However, they are not ideal for throttling due to their linear motion design.

control valve

Selection and Sizing of Control Valves

Choosing the right control valve requires careful consideration of various factors, including the type of fluid, operating temperature and pressure, flow characteristics, and application requirements. Proper sizing is essential to ensure optimal performance. An undersized valve may restrict flow, leading to increased pressure drop and possible system failures, while an oversized valve may result in instability and poor control.

Engineers utilize fluid dynamic principles and various equations to calculate the appropriate valve size. Key parameters include the flow coefficient (Cv), which defines the valve’s capacity to allow fluid flow, and the pressure drop across the valve.

Applications of Control Valves

Control valves are utilized in a wide range of applications. In the oil and gas industry, they regulate the flow of crude oil and natural gas through pipelines. In water treatment facilities, control valves manage the flow of chemicals added for purification. Additionally, in HVAC systems, control valves help maintain temperature and pressure by regulating chilled water or steam.

The Importance of Maintenance

Proper maintenance of control valves is crucial for ensuring their reliability and performance. Regular inspection helps identify wear and tear, leaks, or any operational issues that may arise. Routine maintenance includes checking for proper operation, cleaning, and replacing worn components. By implementing a preventive maintenance schedule, facilities can minimize downtime and extend the lifespan of their control valves.

Conclusion

Control valves are vital components of fluid systems across various industries, ensuring efficient operation and safety. Understanding their functionality, types, and maintenance requirements is essential for engineers and operators. By selecting the right control valve and maintaining it properly, organizations can achieve optimal process control and enhance overall system performance.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025