നവം . 15, 2024 14:07 Back to list

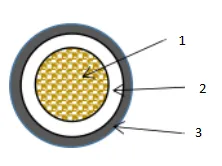

coated wire cable

The Importance of Coated Wire Cables in Modern Applications

Coated wire cables have become an integral component in numerous industries due to their versatility, durability, and safety features. These cables are essentially wire strands that are coated with insulation material, which provides several advantages, making them a preferred choice in various applications such as telecommunications, automotive, aerospace, and construction.

One of the primary benefits of coated wire cables is enhanced durability. The insulation coating protects the bare wires from environmental factors such as moisture, chemicals, and extreme temperatures. This protective layer reduces the risk of corrosion and electrical short-circuiting, thereby extending the lifespan of the cables. In environments where wires are exposed to harsh conditions, such as industrial settings or outdoor installations, coated wire cables offer reliable performance and reduce maintenance costs.

Safety is another significant aspect of using coated wire cables. The insulation serves as a barrier, preventing accidental electrocution and making these cables safer for both users and equipment. In places where multiple cables are bundled together, the coating helps to prevent accidental contact, reducing the risk of electrical fires. Furthermore, many coatings are designed to be flame-retardant or self-extinguishing, adding an extra layer of safety in critical applications.

coated wire cable

In the telecommunications sector, coated wire cables are essential for effective signal transmission

. These cables often feature specific coatings that minimize electromagnetic interference (EMI), ensuring clear communication signals over long distances. With the increasing demand for reliable communication networks, the role of coated wire cables in connecting homes, businesses, and devices cannot be overstated.The automotive industry also benefits from the use of coated wire cables. In modern vehicles, where electronics play a crucial role, these cables are used extensively for wiring harnesses, sensors, and connectivity. The coatings are designed not only to withstand heat and vibrations but also to resist oils and other chemical substances commonly found in vehicles. As electric vehicles (EVs) gain popularity, the demand for high-performance coated wire cables that can handle increased power loads and their environmental impacts will only grow.

Moreover, the construction industry relies heavily on coated wire cables for various applications. From electrical installations to reinforcement in concrete structures, these cables provide strength while ensuring safety and compliance with regulations. Given the increasing emphasis on sustainable building practices, coated wire cables made from environmentally friendly materials are emerging as a preferred choice.

In conclusion, coated wire cables are indispensable in a wide range of applications due to their durability, safety features, and adaptability. As technology evolves, the demand for high-quality coated wire cables will continue to rise, driven by the needs of various industries striving for efficiency and safety. Manufacturers are constantly innovating to enhance the performance characteristics of these cables, ensuring that they can meet the evolving demands of modern technology. Therefore, investing in coated wire cables is a decision that can lead to significant long-term benefits for companies and industries alike.

Share