ഡിസം . 05, 2024 05:40 Back to list

air valve

Understanding Air Valves A Key Component in Pneumatic Systems

Air valves play a crucial role in the realm of pneumatic systems, which harness compressed air to facilitate a wide variety of functions across numerous industries. Their primary purpose is to control the flow and direction of air within these systems, enabling efficient operation and automation of machinery. This article delves into the fundamentals of air valves, their types, applications, and significance.

What is an Air Valve?

An air valve is a mechanical device designed to either block or allow the passage of air within a pneumatic system. It is an essential component for regulating pressure and ensuring the proper functioning of various machines. Air valves can be found in simple applications, such as air compressors, or in more complex systems like robotic automation and pneumatic tools.

Types of Air Valves

Air valves come in several varieties, each serving specific functions

1. Solenoid Valves These valves are controlled by an electric current, enabling automatic operation. When energized, the solenoid moves a plunger that opens or closes the valve, allowing for rapid control over air flow. Solenoid valves are commonly used in automation systems, where quick response times are essential.

2. Manual Valves As the name suggests, these valves require manual operation to open or close. They are typically used in applications where automation isn't necessary. The operator can control the air flow by turning a knob or lever, providing a reliable means of regulation.

3. Pneumatic Valves These valves use compressed air to actuate the valve mechanism. Pneumatic valves are often employed in systems that require high-speed operations, such as conveyor systems or robotic arms.

4. Flow Control Valves These valves are specifically designed to regulate the speed of air flow within a system. By adjusting the flow rate, they ensure that downstream components receive a consistent supply of air, which is critical for maintaining system performance.

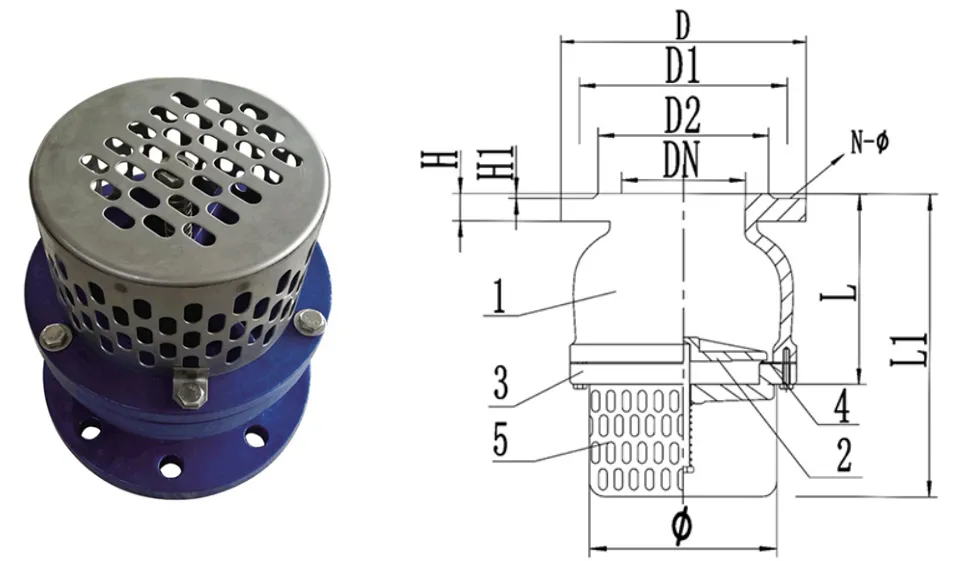

5. Check Valves Designed to allow air to flow in one direction only, check valves prevent backflow that could disrupt the functioning of a pneumatic system. They are vital in maintaining system integrity and protecting downstream components from damage.

air valve

Applications of Air Valves

The versatility of air valves allows them to be used across a wide range of industries and applications, including

1. Manufacturing In manufacturing settings, air valves control the operation of pneumatic tools and machinery. They help automate processes, improve precision, and enhance overall productivity.

2. Construction Air valves are used in construction equipment, such as pneumatic drills and hammers, enabling efficient and powerful operation. They contribute to the effectiveness of tools that require significant air pressure to perform tasks.

3. Packaging In packaging operations, air valves control the flow of air in pneumatic conveyors, ensuring items move smoothly and efficiently through the production line.

4. Automotive Air valves are utilized in automotive assembly lines, where they operate tools and machinery that require pneumatic power. They help streamline the production process and enhance efficiency.

Importance of Air Valves

The significance of air valves cannot be overstated. They ensure the smooth operation of pneumatic systems, which are critical in many industrial applications. Without proper air valve functionality, systems could experience leaks, pressure drops, and inefficiencies that lead to increased operational costs and downtimes.

Moreover, air valves contribute to safety by preventing uncontrolled air flow, which can create hazardous conditions. By controlling the air flow and pressure, they help protect equipment, enhance reliability, and improve overall system performance.

Conclusion

In conclusion, air valves are an integral part of pneumatic systems, playing a vital role in controlling air flow and maintaining efficiency across various industries. With different types available for diverse applications, understanding their function and importance is essential for anyone involved in the design, maintenance, or operation of pneumatic systems. As technology continues to advance, the development and innovation of air valves will undoubtedly keep pace, ensuring they remain a cornerstone of modern industrial operations.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025