നവം . 12, 2024 02:42 Back to list

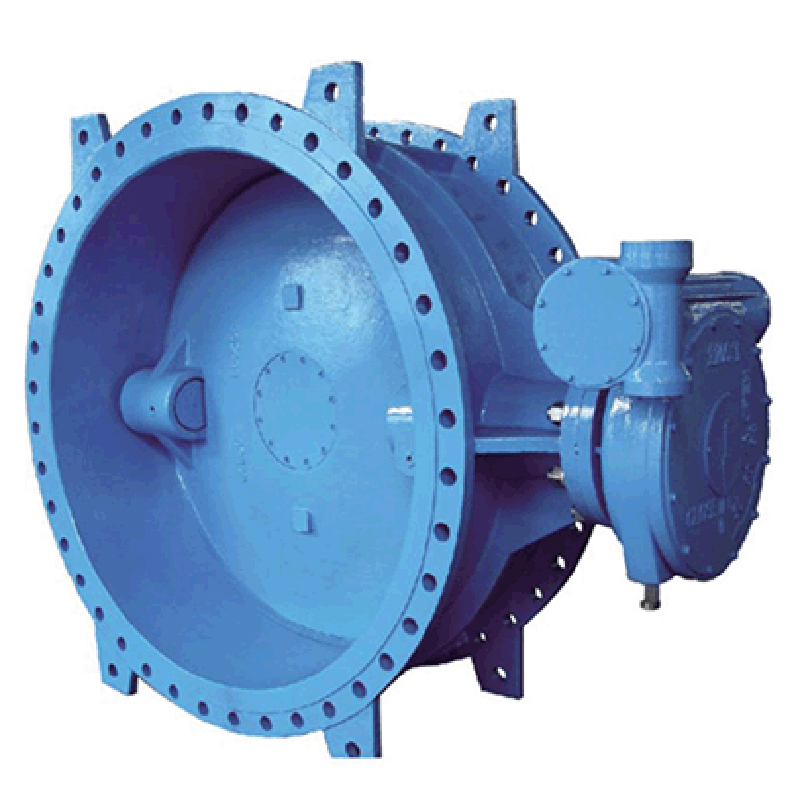

1400mm butterfly valve

The 1400mm Butterfly Valve A Comprehensive Overview

In the realm of industrial applications, the butterfly valve stands out as one of the most efficient and versatile components for controlling fluid flow. The 1400mm butterfly valve, specifically, is designed to meet the demands of large-scale operations, commonly found in water treatment plants, oil and gas industries, and various manufacturing processes. This article delves into the characteristics, applications, advantages, and maintenance of the 1400mm butterfly valve.

What is a Butterfly Valve?

A butterfly valve consists of a rotating disc that controls the flow of fluid through a pipe by rotating around a fixed axis. When the disc is parallel to the flow, the valve is open, allowing fluid to pass through. Conversely, when the disc is perpendicular, the valve is closed, reducing or stopping the flow altogether. Butterfly valves are known for their simple design, compact structure, and lightweight nature, making them ideal for large diameter pipes, such as the 1400mm variant.

Characteristics of the 1400mm Butterfly Valve

The 1400mm butterfly valve is crafted to handle significant pressure and temperature variations, ensuring durability and reliability in various conditions. Key characteristics include

1. Size With a nominal diameter of 1400mm, this type of valve can manage substantial fluid volumes, making it suitable for large-scale operations.

2. Materials Typically constructed from durable materials such as stainless steel, ductile iron, or PVC, the choice of material impacts the valve's resistance to corrosion and wear.

3. Actuation This valve can be operated manually or automatically, with options including pneumatic, electric, or hydraulic actuators. The choice depends on the operational requirements and level of automation desired.

4. Sealing Mechanisms The sealing performance is crucial to prevent leaks. Different seat materials are available, such as EPDM or PTFE, to ensure a tight seal and compatibility with various fluids.

Applications of the 1400mm Butterfly Valve

Due to its design and functionality, the 1400mm butterfly valve finds applications across several industries

1. Water Treatment In municipal water supply systems, these valves regulate water flow, contributing to efficient processing.

3. Power Generation In power plants, this valve controls the circulation of cooling water and steam, critical for maintaining operational efficiency.

1400mm butterfly valve

4. Chemical Industry The valve is used to manage the flow of chemicals, allowing for safe handling and effective process management.

Advantages of the 1400mm Butterfly Valve

The popularity of the 1400mm butterfly valve stems from various advantages

- Space-Efficiency Its compact design requires less space compared to traditional valves, facilitating installation in restricted areas.

- Low Operating Torque The design enables quick actuation with minimal effort, which is particularly beneficial in automatic systems.

- Versatile Flow Control The butterfly valve can be used for throttling as well as isolation, providing flexibility in various applications.

- Cost-Effectiveness Generally, butterfly valves are more affordable than other valve types, making them a cost-effective solution for large-diameter applications.

Maintenance and Best Practices

To ensure the longevity and optimal performance of the 1400mm butterfly valve, regular maintenance is paramount. Here are some best practices

1. Routine Inspection Check for leaks, wear on the sealing surfaces, and overall valve condition at regular intervals.

2. Lubrication Ensure that the actuator and moving parts are adequately lubricated to prevent rust and enhance operation efficiency.

3. Manual Testing Periodically test the manual operation of the valve to ensure reliability in case of actuator failure.

4. Emissions Assessment Regularly assess for any signs of leakage, especially in critical applications, to maintain safety and environmental standards.

Conclusion

The 1400mm butterfly valve is a critical component in various industrial settings, offering efficient flow control solutions. With its robust design and versatility, it meets the needs of industries that require large-diameter piping solutions. Proper understanding of its features, applications, benefits, and maintenance practices will ensure optimal performance and longevity of this essential valve type in sophisticated operational environments.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025