Дек . 17, 2024 05:41 Back to list

y type strainer

Understanding Y-Type Strainers A Comprehensive Guide

Y-type strainers are essential components widely used in various industrial processes. Designed to filter out impurities and contaminants from liquids and gases, Y-type strainers are crucial for ensuring operational efficiency and prolonging the lifespan of equipment. This article delves into the fundamental aspects of Y-type strainers, their design, applications, benefits, and maintenance.

What is a Y-Type Strainer?

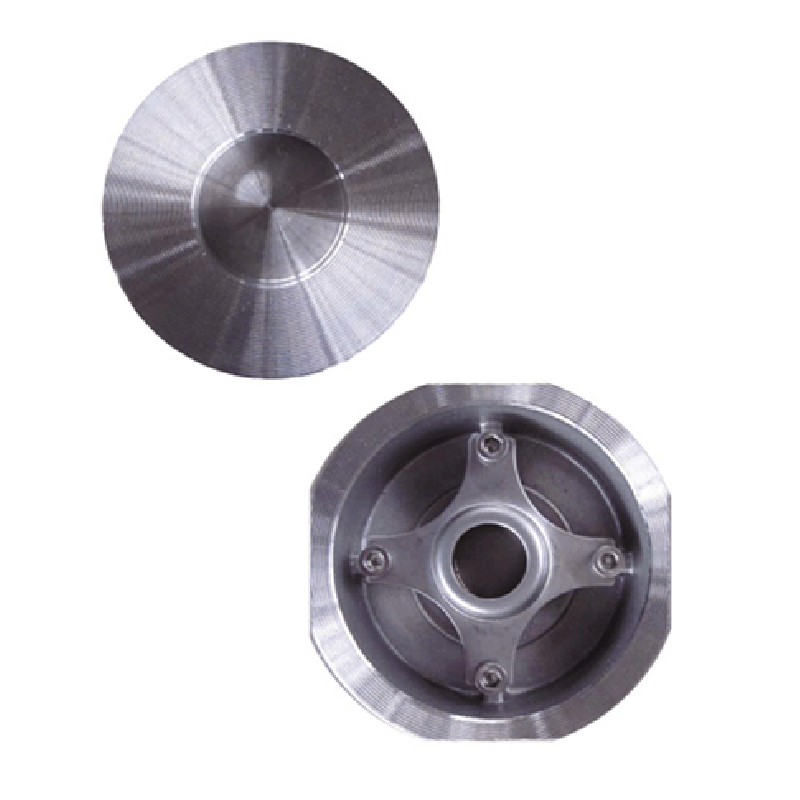

A Y-type strainer, also known as a Y strainer or wedge strainer, features a distinctive 'Y' shape that allows it to be installed in a piping system at a slight angle. This unique design facilitates the efficient trapping of debris while allowing for uninterrupted flow. Typically made from materials such as stainless steel, cast iron, or bronze, Y-type strainers stand up to most working environments and are suitable for a wide range of applications.

Design and Functionality

The primary function of a Y-type strainer is to protect equipment such as valves, pumps, and nozzles from damage caused by solid particles present in the fluid being transported. The strainer consists of a body, a perforated or mesh straining element, and a cover. Fluids enter the strainer through the inlet, pass through the straining element, and exit through the outlet, leaving behind any debris collected in the strainer.

One of the key features of Y-type strainers is their ease of maintenance. The straining element can typically be removed easily for cleaning or replacement, minimizing downtime in operations. Additionally, the 'Y' shape allows for a gravity-assisted cleaning process, as the debris can settle at the bottom of the strainer, making it easier to drain out.

Applications

Y-type strainers are used across various industries, including

y type strainer

1. Water Supply Installed in water treatment facilities and municipal supply systems to prevent debris from damaging pumps and valves. 2. Chemical Processing Protects equipment in corrosive environments from particulate contamination, ensuring a smooth operation. 3. Oil and Gas Used in pipeline systems to filter out sand and other solids, maintaining the integrity of pumps and other downstream equipment. 4. HVAC Systems Ensures clean water circulation in heating and cooling systems, preventing blockages that could cause equipment failure. 5. Food and Beverage Maintains hygiene standards by filtering out unwanted particles, thus guaranteeing the quality of the final product.

Benefits

The advantages of using Y-type strainers are numerous

1. Effective Filtration Y-type strainers offer efficient separation of solid particles from fluids, which is vital for many operation’s success. 2. Cost-Effective By protecting essential equipment, Y-type strainers help reduce maintenance costs and prolong the lifespan of components, leading to overall cost savings. 3. Versatility Suitable for various applications across multiple industries, Y-type strainers can handle different fluid types and sizes, making them adaptable to numerous systems. 4. Simplicity of Maintenance The straightforward design allows for quick cleaning and maintenance, minimizing the need for specialized tools or labor.

Maintenance Tips

To ensure the optimal performance of Y-type strainers, regular maintenance is crucial. Below are some tips

1. Regular Inspection Check strainers at regular intervals to assess the build-up of debris and overall condition. 2. Cleaning Schedule Establish a cleaning schedule based on the type of fluid and expected debris levels to prevent clogging. 3. Replace Straining Elements If the straining element shows signs of wear and tear or significant damage, replace it promptly to ensure continuous protection. 4. Monitor System Performance Keep an eye on pressure gauges and flow rates; a significant drop may indicate that the strainer needs cleaning or replacement.

Conclusion

Y-type strainers play a vital role in ensuring the smooth operation of various systems by filtering out unwanted particulates. Their design, efficiency, and ease of maintenance make them a popular choice across many industries. By understanding the importance of Y-type strainers and abiding by maintenance best practices, industries can optimize equipment performance, enhance productivity, and reduce operational costs. Whether in water supply systems, chemical processing plants, or HVAC setups, Y-type strainers are indispensable tools for sustaining operational integrity.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025