Дек . 16, 2024 14:21 Back to list

wafer type butterfly valve dimension

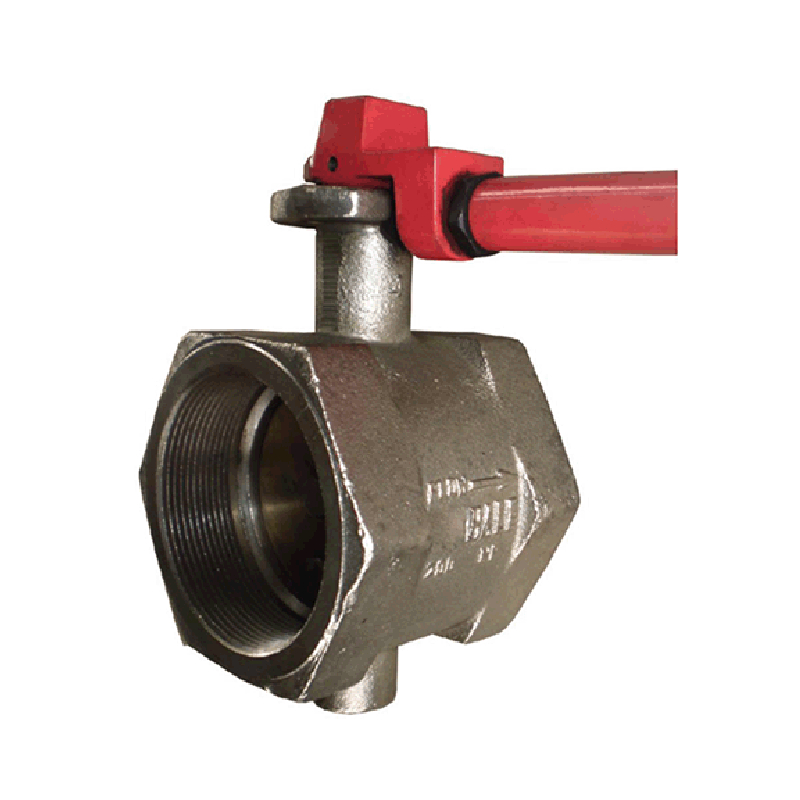

Understanding Wafer Type Butterfly Valve Dimensions

In various industrial applications, especially in fluid control, the selection of the appropriate valve is crucial. Among the different types of valves available, the wafer type butterfly valve has gained significant popularity due to its simplicity, compact design, and effectiveness in controlling flow. This article will delve into the dimensions of wafer type butterfly valves, their importance, and how they relate to various industrial applications.

What is a Wafer Type Butterfly Valve?

A wafer type butterfly valve is a quarter-turn valve that uses a rotating disc to control the flow of fluid. Unlike other valve types, it has a unique design that allows it to be sandwiched between two flanges, making it suitable for installations where space is limited or weight needs to be minimized. The operation of the butterfly valve is straightforward when the disc is parallel to the flow, the valve is open, and when it is perpendicular, the valve is closed.

Importance of Dimensions

The dimensions of a wafer type butterfly valve are critical for several reasons

1. Compatibility with Piping Systems The valve's dimensions must match the size and specifications of the piping systems in which they are installed. Standardized dimensions ensure that the valve fits seamlessly between flanges without the need for custom installations.

2. Flow Rate and Pressure The effective flow rate and the pressure drop across the valve can be influenced by its diameter and geometry. Proper sizing facilitates optimal flow characteristics and minimizes energy consumption.

3. Installation and Maintenance Dimensions influence the ease of installation and the ability to access the valve for maintenance or repairs. A well-sized valve ensures that it can be easily maneuvered into place and serviced later on.

Key Dimensions of Wafer Type Butterfly Valves

wafer type butterfly valve dimension

When selecting a wafer type butterfly valve, several key dimensions must be considered

1. Valve Size (Diameter) The nominal diameter of the valve corresponds to the pipe size and is typically expressed in inches or millimeters. Common sizes range from 2 inches to 48 inches (50mm to 1200mm), depending on the application.

2. Face-to-Face Dimensions This refers to the distance between the two ends of the valve that face the flanges. It is crucial for ensuring that the valve fits well within a given space and aligns correctly with other components in the piping system.

3. Thickness The thickness of the valve body can affect its pressure rating and durability. Thicker bodies can withstand higher pressures and more aggressive fluid conditions, making them suitable for harsher environments.

4. Disc Thickness and Diameter These dimensions affect the flow characteristics of the valve and its sealing capability. It's important to choose a disc design that balances performance with the requirement for a robust seal.

5. Connection Type Wafer type butterfly valves typically feature drill patterns that align with the flanges they are installed between. Understanding the drilling pattern dimensions and flange type compatibility is essential in ensuring a secure connection.

6. Material Specifications While not a dimensional aspect per se, the material can influence the external dimensions of the valve. Different materials have varying density, and appropriate material selection should consider the fluid types, temperature, and application environment.

Conclusion

Wafer type butterfly valves are invaluable components in modern industrial applications. Their dimensions play a pivotal role in their performance, installation, and longevity within a fluid control system. When selecting a wafer type butterfly valve, it is essential to understand not only the specific dimensional requirements but also how these dimensions impact the valve's functionality and suitability for certain applications. By carefully considering these factors, engineers and maintenance professionals can ensure that they select the right valve for their needs, optimizing both efficiency and safety in fluid management systems.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025