Ное . 04, 2024 23:34 Back to list

rubber expansion joint price

Understanding the Pricing of Rubber Expansion Joints

Rubber expansion joints are vital components in various industrial and infrastructure applications. They are designed to absorb vibration, reduce noise, and accommodate the thermal expansion and contraction of piping systems. The importance of these joints cannot be overstated, as they ensure the smooth operation of machinery and systems, preventing damage due to stress and movement. However, one of the key considerations for engineers and procurement professionals is the cost associated with rubber expansion joints. In this article, we will delve into the factors that influence the pricing of these essential components and provide insights into how to navigate the market effectively.

Factors Influencing Price

1. Material Composition The type of rubber used in the manufacturing of expansion joints plays a significant role in their pricing. Common materials include natural rubber, synthetic rubber, and various blends tailored for specific applications. Higher-quality, more durable materials often come at a higher price point, but they can lead to longer service life and reduced maintenance costs, making them a better long-term investment.

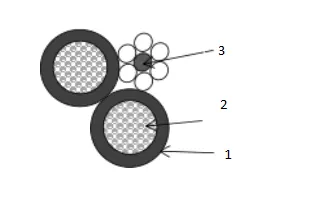

2. Size and Configuration Rubber expansion joints come in various sizes and configurations to suit different piping systems. Larger joints or those with complex designs (such as triple arch joints) typically cost more due to increased material and manufacturing complexities. When selecting an expansion joint, it is crucial to consider the specific needs of the application to avoid unnecessary expenditures.

3. Pressure and Temperature Ratings The operational parameters of the expansion joints, such as their pressure and temperature ratings, also impact pricing. Higher-rated joints are constructed to withstand more demanding environments, which necessitates advanced materials and engineering, thereby increasing their cost. It is essential to match the joint to the system’s operational requirements to ensure safety and efficiency.

4. Manufacturing Process The method of production can influence the final price of rubber expansion joints. Some manufacturers utilize advanced techniques such as computer-aided design (CAD) and manufacturing (CAM), which can improve precision and consistency but may increase costs. Additionally, joints produced in smaller batches may have higher per-unit costs compared to those manufactured on a large scale.

rubber expansion joint price

5. Brand Reputation and Warranty Established manufacturers often command higher prices due to their reputation for quality and reliability. A reputable brand is likely to provide better warranties and support, which can provide peace of mind. When considering the total cost of ownership, it may be worth investing in a more expensive but reliable product.

Navigating the Market

When searching for rubber expansion joints, it is crucial to conduct thorough market research. Comparing prices from different suppliers can provide insight into what constitutes a reasonable price range. However, it is essential to consider the total cost of acquisition, which includes not just the initial purchase price, but also installation and potential maintenance costs.

Additionally, consulting with industry professionals can provide valuable recommendations on the best products for specific applications. In some cases, bulk purchasing or long-term contracts may offer significant savings, especially when dealing with large-scale projects requiring numerous expansion joints.

Conclusion

The price of rubber expansion joints can vary significantly based on a multitude of factors, including material quality, size, pressure ratings, manufacturing processes, and brand reputation. Understanding these elements can help engineers and procurement specialists make informed decisions that balance cost against performance and reliability. As with any industrial component, investing in high-quality rubber expansion joints can enhance operational efficiency, reduce maintenance costs, and ensure the longevity of piping systems. Ultimately, the goal is to find a solution that meets both budgetary constraints and technical requirements, leading to successful project outcomes in industrial and infrastructure applications.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025