Ное . 29, 2024 19:28 Back to list

Understanding the Benefits and Applications of Rubber Expansion Joints in Engineering

Understanding Reflex Rubber Expansion Joints

In various industrial applications, managing vibrations, thermal expansion, and chemical resistance is vital to ensure the longevity and efficiency of piping systems. One solution that has gained popularity in a range of sectors is the Reflex Rubber Expansion Joint. These joints are designed specifically to address the challenges presented by dynamic and thermal stresses in piping systems.

What are Reflex Rubber Expansion Joints?

A Reflex Rubber Expansion Joint is an engineered component that allows for movement within a piping system while simultaneously minimizing the stress that movement may cause. These joints are constructed from layers of rubber and fabric, providing flexibility, resilience, and resistance to environmental factors. The term reflex refers to the joint’s ability to return to its original shape after deformation, making it an ideal choice for applications facing continuous movement.

Functionality and Benefits

The primary function of Reflex Rubber Expansion Joints is to absorb vibrations and accommodate thermal expansion and contraction of piping systems. As liquids and gases flow through pipes, they can create pressure fluctuations and vibrations that, if left unchecked, might lead to premature failures. Expansion joints can effectively dampen these vibrations, leading to increased system reliability.

Additionally, these joints are useful in compensating for misalignment in piping. Over time, shifts in ground support or inherent imperfections in installation can lead to angular misalignments. Reflex Rubber Expansion Joints can absorb these misalignments, preventing undue stress on the pipeline and maintaining the integrity of the system.

Another significant benefit of Reflex Rubber Expansion Joints is their chemical resistance. Depending on the specific rubber compound used in the construction, these joints can withstand a variety of harsh chemicals, which makes them suitable for applications in chemical processing, wastewater management, and other industries where exposure to corrosive materials is a concern.

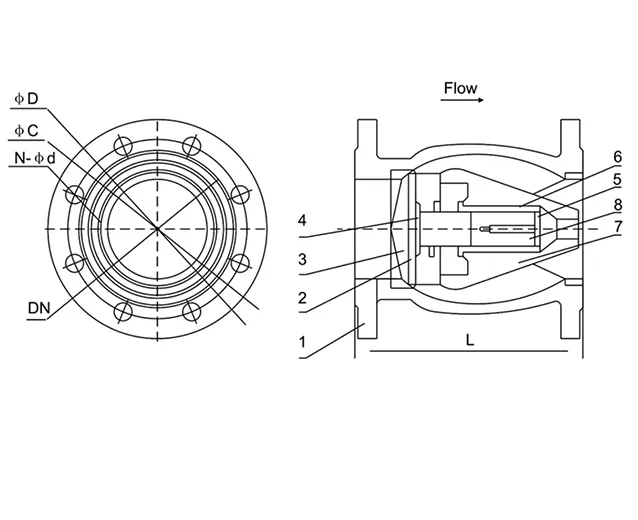

reflex rubber expansion joint

Applications

Reflex Rubber Expansion Joints are particularly versatile and can be found in numerous applications across different industries. In the HVAC sector, for instance, these joints are often utilized in ducting systems to manage thermal and vibrational stresses. Similarly, in the petrochemical industry, they help mitigate the effects of heat expansion and vibrations due to fluid movement in pipelines.

Water treatment facilities also benefit from Reflex Rubber Expansion Joints, as they facilitate the necessary expansion and contraction of pipes while effectively absorbing vibrations from pumps and motors. Moreover, they play a key role in the construction and maintenance of power plants, where they help manage stresses caused by thermal cycles and fluid dynamics.

Installation and Maintenance

Proper installation is crucial when utilizing Reflex Rubber Expansion Joints to ensure they perform effectively. It is important to follow manufacturer guidelines closely and ensure that pipe alignments are correct prior to installation. Additionally, avoiding excessive tension or compression during the installation process can extend the joint’s lifespan.

Routine maintenance checks can also aid in prolonging the service life of these joints. Inspecting for wear and tear, ensuring that the components are securely fastened, and checking for signs of leakage or degradation can help in identifying potential issues before they escalate.

Conclusion

In summary, Reflex Rubber Expansion Joints are essential components in modern industrial piping systems, designed to manage the complexities associated with thermal expansion, vibrations, and misalignment. Their unique construction provides significant benefits, including flexibility, resilience, and chemical resistance, making them a go-to solution across various industries. Investing in high-quality Reflex Rubber Expansion Joints not only enhances the performance and lifespan of piping systems but also contributes to the overall safety and efficiency of industrial operations.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025