Авг . 23, 2025 16:08 Назад на списокот

Priming a Pump with a Foot Valve with Strainer

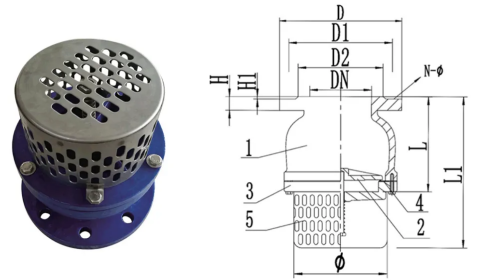

Priming a pump is a crucial step to ensure it operates efficiently, and a foot valve with strainer plays a vital role in this process. This component not only prevents water from flowing back out of the pump and suction line but also filters out debris that could damage the pump. 2025 Hebei honest industrial group Co.,Ltd., established in 2006 as a professional manufacturer of middle & low pressure valves with a 15,000-square-meter facility, produces high-quality foot valve, foot check valve, and foot valve with strainer products. Their ISO and CE certifications guarantee these valves meet strict standards, making them reliable for pump priming in various applications. This article guides you through the process of priming a pump using a foot valve with strainer, highlighting the importance of each component and offering tips for success.

Role of Foot Valve in Pump Priming

- Maintaining Prime: A foot valve is a one-way valve installed at the end of the suction line, submerged in the fluid source. When priming the pump, it allows fluid to flow into the suction line and pump but closes to prevent backflow once the pump is running. This keeps the line filled with fluid, ensuring the pump can continue to draw water without needing to be re-primed repeatedly.

- Creating a Seal: The foot valve creates an airtight seal in the suction line, which is essential for priming. Without this seal, air would enter the line, breaking the vacuum and making it impossible for the pump to draw fluid. A well-functioning foot valve ensures that the only way fluid can move is into the pump, maintaining the necessary pressure for operation.

- Supporting Pump Efficiency: By preventing backflow, the foot valve reduces the workload on the pump. Without it, the pump would have to re-pressurize the line each time it starts, wasting energy and increasing wear. This makes the foot valve a key component in maintaining long-term pump efficiency.

Benefits of Foot Valve with Strainer

- Debris Filtration: The strainer attached to a foot valve with strainer traps particles like sand, leaves, and small rocks, preventing them from entering the pump. This is especially important in well water systems or outdoor ponds, where debris is common. Without this filtration, debris could clog the pump impeller, causing damage and reducing performance.

- Reducing Maintenance Needs: By keeping debris out of the pump, a foot valve with strainer minimizes the need for frequent cleaning and repairs. The strainer itself is easy to remove and clean, making maintenance quick and simple. This is a significant advantage over a standard foot valve, which would allow debris to pass through and potentially cause costly damage.

- Extending Pump Lifespan: The combination of backflow prevention and debris filtration provided by a foot valve with strainer helps extend the pump’s lifespan. By protecting the pump from damage and reducing stress, this component ensures the pump operates smoothly for years longer than it would without proper protection.

Steps to Prime a Pump Using Foot Check Valve

|

Step |

Action |

Why It Matters |

|

Inspect the Foot Check Valve |

Check the foot check valve for damage, ensuring the flap moves freely and the seal is intact. |

A damaged valve won’t seal properly, making priming impossible. |

|

Fill the Suction Line |

Pour water into the pump inlet until the suction line is full, allowing water to flow down to the foot check valve. |

This removes air from the line, creating the vacuum needed for priming. |

|

Close Pump Inlet |

Seal the pump inlet to prevent air from entering while starting the pump. |

Maintains the vacuum in the suction line, allowing the pump to draw fluid. |

|

Start the Pump |

Turn on the pump and monitor for water flow. If water flows steadily, the pump is primed. |

Confirms that the foot check valve is working and the priming process is successful. |

|

Check for Leaks |

Inspect the foot check valve and connections for leaks after priming. |

Leaks can break the vacuum, requiring re-priming and potentially damaging the pump. |

This table outlines the key steps for priming a pump using a foot check valve, ensuring a smooth and effective process.

Troubleshooting Foot Valve Issues During Priming

- Air Leaks in the Foot Valve: If the pump fails to prime, an air leak in the foot valve is a common culprit. Check the valve’s gasket for cracks or wear, and replace it if necessary. Also, ensure the valve is tightly secured to the suction line—loose connections can allow air to enter, breaking the vacuum.

- Clogged Strainer on Foot Valve with Strainer: A clogged strainer on a foot valve with strainer will restrict water flow, making it difficult to prime the pump. Remove the strainer and clean it thoroughly, removing any debris that may be blocking the openings. Reattach the strainer securely before attempting to re-prime.

- Stuck Flap in Foot Check Valve: The flap in a foot check valve can get stuck closed due to debris or corrosion, preventing water from flowing into the suction line. Disassemble the valve, clean the flap and seat, and lubricate moving parts if needed. This should restore proper movement and allow the valve to function correctly.

Foot Valve FAQS

How Often Should a Foot Valve Be Replaced?

A well-maintained foot valve typically lasts 5–7 years. However, if you notice leaks, difficulty priming the pump, or visible damage, it should be replaced immediately. In harsh environments with high debris or corrosive fluids, replacement may be needed more frequently.

Can a Foot Valve with Strainer Be Used in Saltwater Systems?

Yes, but it’s important to choose a foot valve with strainer made from corrosion-resistant materials like stainless steel. Saltwater is highly corrosive, and a standard metal valve would degrade quickly, leading to failure. Stainless steel models are designed to withstand saltwater environments.

What’s the Difference Between a Foot Valve and a Foot Check Valve?

There is no significant difference—foot valve and foot check valve are often used interchangeably. Both are one-way valves installed at the end of a suction line to prevent backflow and aid in pump priming. The term “check valve” refers to their one-way functionality.

How Do I Know if My Foot Valve is Clogged?

Signs of a clogged foot valve include difficulty priming the pump, reduced water flow, and unusual noises from the pump. If you suspect a clog, remove the valve and check the strainer (if equipped) for debris. Cleaning the strainer or valve should restore proper function.

Where Can I Purchase High-Quality Foot Valve Products?

2025 Hebei honest industrial group Co.,Ltd. offers a range of high-quality foot valve, foot check valve, and foot valve with strainer products, designed for reliable performance in various applications. Visit their website to explore their selection and find the perfect valve for your pump priming needs.

Споделете

-

The Importance of a Y Strainer in Pump ProtectionВестиAug.23,2025

-

Stainless Steel Ball Check Valve for High-Purity ApplicationsВестиAug.23,2025

-

Common Applications for Wafer Type Butterfly ValvesВестиAug.23,2025

-

Seat Options for a 12 Inch Knife Gate ValveВестиAug.23,2025

-

The Lifespan of a Typical Dismantling JointВестиAug.23,2025