Сеп . 22, 2024 06:42 Back to list

pipe dismantling joint

Understanding Pipe Dismantling Joints A Key Component in Pipeline Systems

In the world of plumbing and pipeline systems, efficiency and flexibility are paramount. One essential component that plays a crucial role in achieving these goals is the pipe dismantling joint. This specialized fitting allows for the easy disassembly of pipes in various applications, making maintenance and repairs significantly simpler and more efficient.

What is a Pipe Dismantling Joint?

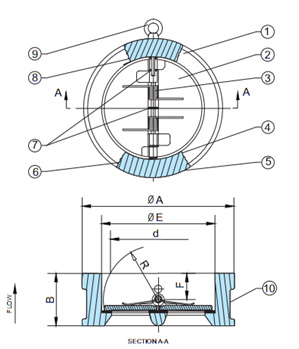

A pipe dismantling joint is a type of connection designed to facilitate the removal of pipe sections without compromising the integrity of the entire system. Typically installed between two pipe segments, it features a unique design that allows for axial movement. This means that when maintenance is required, operators can slide one section of pipe away from the joint, creating a gap that enables inspection, repair, or replacement without the need to dismantle the entire pipeline.

Applications of Pipe Dismantling Joints

These joints are versatile and find applications in various sectors, including water supply, wastewater treatment, and industrial piping systems. In water supply systems, for instance, dismantling joints are often installed at strategic points to allow easy access for repairs or upgrades. In wastewater treatment, they can help in maintaining pumps and valves, reducing downtime and ensuring the system operates efficiently.

Advantages of Using Dismantling Joints

pipe dismantling joint

The primary advantage of using pipe dismantling joints lies in their ability to simplify maintenance. Traditional piping systems often require extensive disassembly, which can be time-consuming and costly. In contrast, dismantling joints allow for quick access to critical components, leading to reduced labor costs and minimal disruption to service. Moreover, they contribute to the longevity of pipeline systems by making it easier to monitor and maintain various components.

Another significant benefit is that dismantling joints can accommodate slight misalignments and thermal expansions. This flexibility is particularly valuable in large-scale industrial applications where temperature fluctuations can cause pipe movements. The ability to accommodate these changes without affecting the overall system integrity is a major advantage of using dismantling joints.

Installation and Maintenance Considerations

Installing pipe dismantling joints requires proper planning and execution. The joint must be compatible with the type of pipes used in the system, and careful attention must be paid to the alignment during installation. Regular maintenance checks should be performed to ensure that the joint remains functional and free from corrosion or damage. This proactive approach can help prevent potential issues that could disrupt the entire system.

Conclusion

In summary, pipe dismantling joints are an invaluable component in modern pipeline systems. Their unique design facilitates easy access for maintenance and repairs, significantly enhancing the efficiency of plumbing operations. As industries continue to evolve and seek more effective solutions for managing their pipeline systems, the importance of dismantling joints is likely to grow. Whether in water supply, wastewater management, or industrial applications, these joints are instrumental in ensuring operational efficiency, reducing maintenance costs, and prolonging the lifespan of pipelines. By understanding their functionality and benefits, operators can better appreciate how these joints contribute to the overall success of their systems.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025