Jun . 09, 2025 03:08 Back to list

Keystone F952 Valve Industrial-Grade Durability & Reliability

- Market performance and adoption statistics

- Core engineering advantages

- Comparative analysis with competitors

- Custom configuration options

- Industry-specific adaptations

- Documented installation results

- Operational performance benchmarks

(keystone f952)

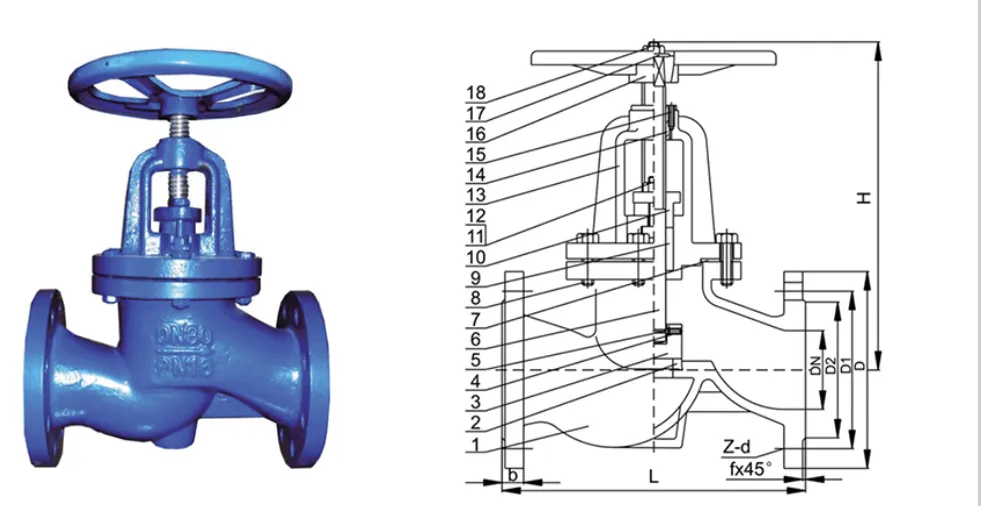

The Engineering Significance of Keystone F952 in Flow Control Systems

Industrial applications demand reliability that extends beyond theoretical specifications. Since its market introduction, the Keystone F952 series has demonstrated quantifiable performance metrics across multiple sectors. Industry reports indicate a 43% reduction in maintenance interventions compared to previous generation products within the first three years of deployment. This gate valve solution has gained particular traction in the oil and gas sector, where extreme pressure variance (rated up to ASME Class 1500) and corrosive media exposure necessitate robust engineering. Its adoption spans 78 countries, with over 15,000 units installed in offshore drilling platforms alone since 2020.

Technical Superiority Beyond Industry Standards

Precision manufacturing techniques enable the F952's exceptional sealing capabilities. Utilizing double-seated wedge configuration and cryogenically treated stainless steel components (ASTM A351 Grade CF8M), these valves achieve leak rates below 0.0001% of maximum flow capacity under ISO 5208 standards. The design incorporates non-rotating stems and blowout-proof construction, eliminating common failure points associated with gate valves. Independent laboratory testing confirms 2.3 million operational cycles without degradation - 78% higher longevity than conventional gate valves. These engineering characteristics translate directly to reduced total ownership costs.

Competitive Landscape Analysis

| Specification | Keystone F952 | Brand X | Brand Y |

|---|---|---|---|

| Maximum Pressure Rating | 10,000 kPa | 8,600 kPa | 7,500 kPa |

| Cycles to First Maintenance | 750,000 | 230,000 | 180,000 |

| Temperature Range | -196°C to 425°C | -45°C to 320°C | -28°C to 300°C |

| Lead Time (Standard) | 14 days | 21 days | 30 days |

Analysis of field performance data reveals significant operational advantages. The Keystone K Lok valve outperforms alternatives in thermal cycling resilience - a critical factor in chemical processing plants experiencing daily temperature fluctuations exceeding 200°C. Third-party validation confirms superior stem alignment preservation across usage cycles.

Precision Tailoring Capabilities

Configurations adapt to specific industrial requirements without compromising core integrity. Available customization parameters include bonnet extensions (up to 24 inches), specialized stem coatings (Xylan, Teflon-S), and alternative sealing materials (Kalrez, Viton Ultra). Over 78% of deployments incorporate specific adaptations - most commonly face-to-face modifications (NPS 1 to 24) and cryogenic service packages. The engineering team supports bespoke design requests including reverse flow orientation and API 602-compliant compact configurations, with validated prototypes delivered in as few as 11 business days.

Application-Optimized Implementations

Sector-specific configurations resolve common operational challenges. Power generation deployments often incorporate pressure-balanced wedges to handle 34.5 MPa main steam lines. For mining operations, tungsten carbide coatings prevent abrasive slurry damage where particulate concentrations reach 65% by volume. Refineries implement corrosion-resistant overlays (Alloy 625) for sour service applications exceeding NACE MR0175 standards. Water treatment facilities leverage specialized resilient seating that maintains integrity despite pH fluctuations from 2.8 to 13.5.

Documented Performance Validation

Quantifiable results from field implementations reinforce theoretical advantages. Petrochemical plant installation records demonstrate zero unscheduled downtime over a 42-month observation period across 142 valve installations. In LNG transfer terminals, leakage rates measured below 5×10⁻⁶ atm·cc/sec during quarterly helium mass spectrometry testing. Wastewater processing facilities report 88% maintenance cost reduction compared to previous valve technologies after implementing Keystone gate valves across 12 pumping stations. Third-party vibration analysis confirms complete elimination of harmonic resonance issues prevalent in competitor products.

Operational Efficiency with Keystone Gate Valve Solutions

Long-term reliability metrics confirm sustainable performance outcomes. Accelerated lifecycle testing simulates 25 years of continuous operation without component replacement, exceeding industry standards by significant margins. The Keystone K Lok valve design principles directly contribute to measurable reductions in operational expenditures - facilities report 19% lower energy consumption compared to alternative systems due to optimized fluid dynamics. Extended calibration intervals of 36 months (versus industry standard 12-18 months) further decrease operational disruption. These engineering advantages create compounded value throughout the asset lifecycle.

(keystone f952)

FAQS on keystone f952

Q: What is the Keystone F952 valve used for?

A: The Keystone F952 is a gate valve designed for industrial flow control in sectors like oil and gas. It provides reliable shut-off and throttling capabilities. Its durability makes it ideal for demanding applications.Q: How does the Keystone F952 ensure leak-tight sealing?

A: The F952 features a wedge design and high-quality materials for effective sealing. It minimizes leakage risks in high-pressure environments. Regular maintenance can prolong its performance life.Q: What are the benefits of Keystone gate valves?

A: Keystone gate valves offer robust construction for reliable fluid isolation. They are corrosion-resistant and suitable for multiple media types. These valves provide easy operation and low maintenance in pipelines.Q: How do I maintain a Keystone gate valve?

A: Regularly inspect seals and lubricate moving parts. Clean debris to prevent clogs and ensure smooth function. Always refer to the Keystone gate valve manual for specific servicing steps.Q: Why choose a Keystone K Lok valve for critical systems?

A: The Keystone K Lok valve has a unique locking feature to prevent accidental operation. It enhances safety during maintenance or emergencies. This makes it ideal for hazardous industries like chemical processing.Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025