Nov . 24, 2024 10:26 Back to list

double flanged gate valve

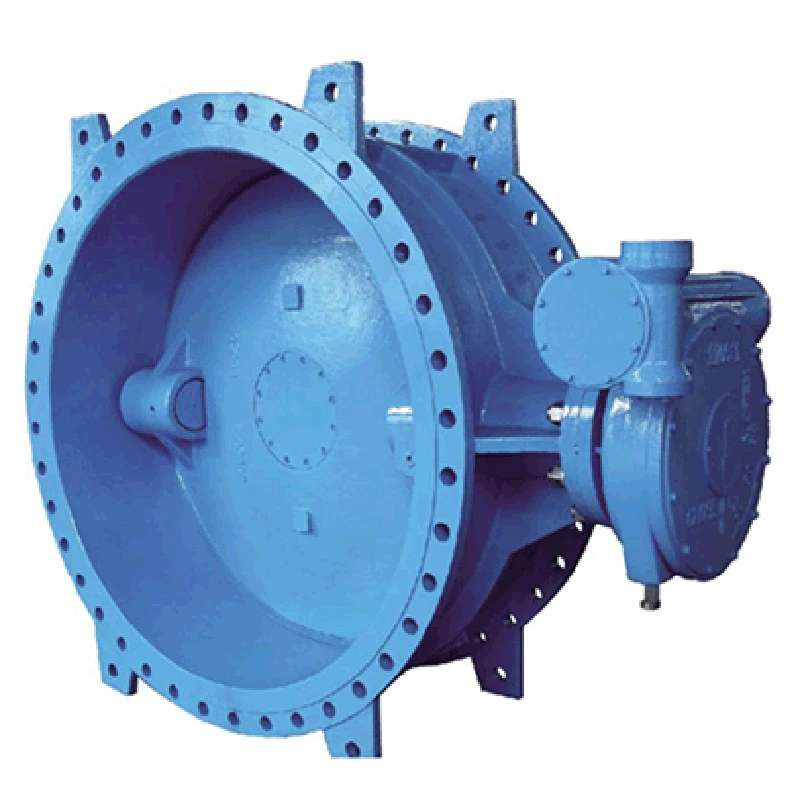

Double Flanged Gate Valve An Overview

The double flanged gate valve is a vital component in many industrial applications, particularly in water, oil, and gas pipelines. Known for its reliability and strong resistance to corrosion, this type of valve plays a crucial role in controlling fluid flow and maintaining system integrity. Its distinct design features two flange connections, which enable it to be securely fitted into a pipeline, making it an ideal choice for various demanding environments.

One of the main advantages of the double flanged gate valve is its excellent sealing capability. The gate valve operates with a gate that moves up and down to either allow or prevent the flow of fluid. When the gate is fully open, there is minimal pressure drop and resistance, allowing for a smooth flow. Conversely, when the valve is closed, the gate creates a tight seal, preventing leaks and ensuring that the system remains pressurized. This is particularly important in applications where the loss of fluid could result in significant operational challenges or safety hazards.

The double flanged design offers enhanced stability and durability. Unlike single flanged models, which may be prone to vibration or movement over time, the double flanged configuration distributes stress evenly across the structure. This not only extends the lifespan of the valve but also ensures that it can withstand high-pressure conditions typical in heavy industrial settings. The flanges allow for easy installation and removal, which is essential for regular maintenance or replacement without the need for extensive modifications to the existing piping system.

double flanged gate valve

Material selection is also a key consideration in the design of double flanged gate valves. Common materials include cast iron, ductile iron, stainless steel, and carbon steel, all of which provide varying levels of strength, corrosion resistance, and temperature tolerance. The choice of material often depends on the specific requirements of the application, such as the type of fluid being transported and the environmental conditions.

In terms of operation, double flanged gate valves can be manually operated or automated using electric or pneumatic actuators. This flexibility allows for integration into sophisticated control systems, enhancing efficiency and ease of use. Operators can monitor and control fluid flow remotely, fostering better resource management and safety oversight.

In conclusion, the double flanged gate valve is an essential piece of equipment in many industries due to its robust construction, reliable performance, and effective sealing capabilities. Its design not only aids in maintaining system integrity but also contributes to operational efficiency, making it a preferred choice for fluid control in various applications. With proper selection, installation, and maintenance, these valves can significantly contribute to the successful operation of industrial processes.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025