Nov . 27, 2024 23:33 Back to list

Water Pressure Relief Check Valve for Efficient Swing Mechanism in Plumbing Systems

The Importance and Functionality of Water Swing Check Valves

In various engineering applications, especially in fluid mechanics, an essential component that ensures the proper functioning of piping systems is the swing check valve. Specifically designed to allow fluid flow in one direction while preventing backflow, these valves play a critical role in maintaining system integrity and efficiency. Among the various types of check valves available, the water swing check valve stands out due to its remarkable features and widespread application in water-related systems.

Understanding Swing Check Valves

A swing check valve operates using a disc that pivots on a hinge - hence the name swing. When water flows in the intended direction, the disc lifts, allowing unrestricted flow. If the water attempts to flow backward, the disc closes under the influence of gravity or back pressure, thereby sealing the valve and preventing reverse flow. This straightforward mechanism is critical for many applications, particularly in water distribution systems, sewage treatment, and industrial processes.

Types and Designs of Water Swing Check Valves

Water swing check valves can be categorized into several designs based on their construction and application requirements. Standard designs include the traditional lift check valve and the globe valve. Each design offers unique advantages, and the choice often depends on specific criteria such as flow rate, pressure, and space constraints.

Materials used in the construction of swing check valves are crucial for ensuring their durability and performance. Common materials include stainless steel, ductile iron, and bronze, which offer excellent resistance to corrosion and wear. The selection of material often relies on the application's specific requirements, including temperature, pressure, and fluid characteristics.

Applications of Water Swing Check Valves

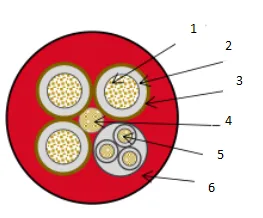

water swing check valve

One of the primary applications of water swing check valves is in municipal water supply systems. As water is distributed from treatment plants to residential and commercial buildings, these valves prevent backflow, which could otherwise lead to contamination of clean water supplies. They also help in maintaining pressure levels within the system, ensuring that water can be efficiently transported to consumers.

Additionally, swing check valves are prevalent in irrigation systems. Farmers and agricultural engineers utilize these valves to manage water flow within irrigation channels, preventing water from flowing back into the source and ensuring that crops receive a consistent supply of water. Their reliability and simple operation make them a preferred choice in this sector.

Industrial applications also benefit from swing check valves, particularly in processes where water is used as a coolant or pivotal component in manufacturing. In such settings, these valves help control flow rates and protect equipment from potential backflow which could lead to damage or inefficient operation.

Advantages of Using Water Swing Check Valves

The advantages of using water swing check valves are numerous. Firstly, their design allows for high-flow capacities, enabling large volumes of water to pass through with minimal resistance or pressure drop. Secondly, as they do not require a power source to operate, they are inherently more reliable and cost-effective compared to powered alternatives. Additionally, maintenance requirements are relatively low, as these valves have fewer moving parts than many other types of check valves.

From an environmental perspective, effective use of swing check valves contributes to resource conservation by minimizing water loss and preventing contamination, thereby ensuring sustainable management of water resources.

Conclusion

In summary, water swing check valves are vital components in numerous applications, offering a reliable solution for unidirectional flow control. Their simple yet effective design, paired with the appropriate material selection, ensures longevity and performance in various environments. As industries and municipalities increasingly recognize the importance of efficient fluid management, the role of swing check valves will undoubtedly continue to grow. Understanding their function, applications, and benefits is crucial for engineers, operators, and anyone involved in fluid management systems, ensuring that they are equipped to maintain efficient and safe systems for the delivery and management of water resources.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025