Nov . 24, 2024 07:01 Back to list

Design and Applications of Semi-Lugged Butterfly Valves in Fluid Control Systems

Understanding the Semi-Lugged Butterfly Valve A Comprehensive Overview

In the ever-evolving world of industrial valves, the semi-lugged butterfly valve is emerging as a vital component across various applications. This innovative design has become increasingly popular due to its unique advantages, such as reduced weight, ease of installation, and exceptional performance. This article will delve into the features, benefits, and applications of semi-lugged butterfly valves, explaining why they are a preferred choice in numerous settings.

What is a Semi-Lugged Butterfly Valve?

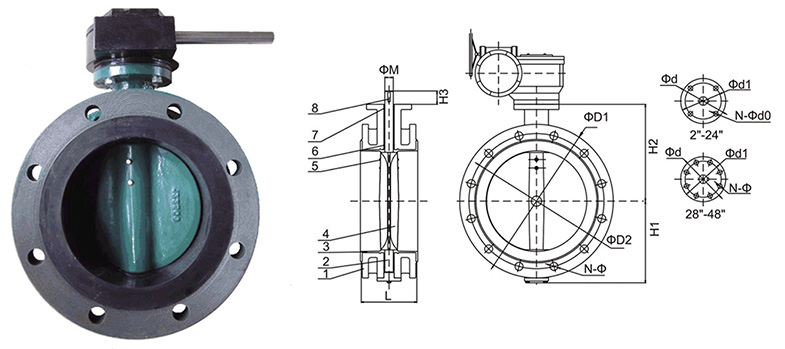

A semi-lugged butterfly valve is a variation of the traditional butterfly valve, which utilizes a disc that rotates around a central axis to regulate fluid flow. The semi-lugged design features lugs that are partially embedded in the valve body. While traditional butterfly valves often have a full-flanged design, the semi-lugged version provides attachment points that facilitate installation while minimizing additional weight. This design is particularly advantageous in applications where space and weight constraints are present.

Key Features of Semi-Lugged Butterfly Valves

1. Compact Design The semi-lugged butterfly valve is designed to be more compact than its full-lugged counterparts. This compactness allows for easier installation in tight spaces, which can be particularly useful in industrial settings with limited access.

2. Material Options These valves are available in various materials, including stainless steel, carbon steel, and plastic. This versatility allows engineers to select the appropriate material based on the specific requirements of the application, such as corrosion resistance or temperature tolerance.

3. Bi-directional Flow Control Semi-lugged butterfly valves can efficiently control flow in both directions, making them versatile for a wide range of applications. This feature is essential in systems that require directional fluid movement, ensuring effective operation.

4. Low Torque Requirement The design of the semi-lugged butterfly valve requires significantly less torque to operate compared to traditional valves. This low torque requirement translates into reduced energy consumption and prolongs the lifespan of the actuator.

Advantages of Using Semi-Lugged Butterfly Valves

1. Weight Efficiency One of the most significant advantages of semi-lugged butterfly valves is their reduced weight. This makes them easier to handle and install, leading to lower labor costs and quicker installation times.

semi lugged butterfly valve

2. Cost-Effective Solution With their simplified design, semi-lugged butterfly valves tend to be more cost-effective than more complex valve types. They also lead to lower maintenance costs due to their durable construction and reliable performance.

3. Enhanced Flow Characteristics The flow characteristics of a semi-lugged butterfly valve are optimized. Their shape and design allow for minimal turbulence and pressure drop across the valve, which can lead to greater system efficiency.

4. Ease of Maintenance The design of these valves contributes to their low maintenance needs. With fewer parts subject to wear and tear, operators can expect longer intervals between service requirements.

Applications of Semi-Lugged Butterfly Valves

Semi-lugged butterfly valves find applications in a variety of industries due to their adaptability and performance efficiency

- Water Treatment Facilities These valves are commonly used to control water flow in pumping systems, ensuring reliable operation in municipal water supply and wastewater systems.

- Chemical Processing In the chemical industry, semi-lugged butterfly valves are utilized to manage the flow of various chemicals, which often requires valves that can handle corrosive substances.

- HVAC Systems Heating, ventilation, and air conditioning systems frequently use these valves to regulate air and fluid flow, optimizing system efficiency and performance.

- Food and Beverage Industry The hygienic design of semi-lugged butterfly valves makes them suitable for food processing applications, where cleanliness and reliability are paramount.

Conclusion

The semi-lugged butterfly valve has become a crucial element in many industries due to its compact design, low weight, cost-effectiveness, and reliable performance. As industries continue to evolve and require more efficient solutions, these valves provide an effective means of controlling fluid flow across various applications. By understanding the features and benefits of semi-lugged butterfly valves, engineers and operators can make informed decisions that enhance operational efficiency and reliability in their respective fields. As technology advances, the versatility of these valves is poised to meet the demands of future industrial applications.

Share