Sep . 14, 2024 13:39 Back to list

lug type butterfly valve

Understanding Lug-Type Butterfly Valves Functionality and Applications

Lug-type butterfly valves are a critical component in various industrial applications, serving as effective flow control devices. These valves are particularly valued for their versatility, reliability, and ease of installation, making them a staple in numerous sectors, including water treatment, HVAC systems, and chemical processing.

Design and Functionality

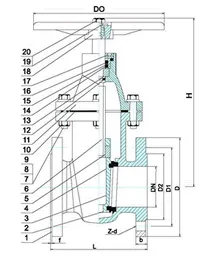

The lug-type butterfly valve consists of a circular disc that rotates around a central axis within a pipe. Unlike a traditional wafer-type valve, a lug-type butterfly valve features threaded lugs on the valve body, allowing it to be bolted directly to the flange of a pipe. This design provides the advantage of being able to isolate the valve from the piping system for maintenance or replacement without the need for additional supports or disconnecting downstream piping.

The operation of a lug-type butterfly valve is straightforward. When the handle is turned, the disc within the valve pivots to either an open or closed position, allowing or restricting the flow of fluid. Because of their simple design, these valves can be operated manually or automatically, with options for electric actuators or pneumatic controls to enhance operational efficiency.

Advantages of Lug-Type Butterfly Valves

One of the most significant advantages of lug-type butterfly valves is their space efficiency. They are typically lighter and more compact than traditional gate or globe valves, making them suitable for installations where space is limited. Moreover, their streamlined design reduces pressure loss and enhances the flow characteristics of the system.

lug type butterfly valve

Lug-type butterfly valves are also known for their durability and resistance to wear and tear. They can be constructed from a variety of materials, including stainless steel, cast iron, and plastic, allowing them to resist corrosion and adapt to different operating environments. This flexibility in material selection makes them ideal for both aggressive chemicals and water applications.

Applications of Lug-Type Butterfly Valves

The versatility of lug-type butterfly valves enables their use in a wide array of industries. In water treatment facilities, they are employed for controlling the flow of water through pipelines, allowing for effective management of water distribution systems. In heating, ventilation, and air conditioning (HVAC) applications, these valves help regulate airflow, contributing to energy efficiency and temperature control.

Chemical processing plants often rely on lug-type butterfly valves for their ability to handle caustic substances. Their tight sealing capabilities ensure that hazardous fluids do not leak, thus protecting personnel and the environment. Additionally, in mining and mineral processing, these valves are used to manage the flow of slurries and other abrasive materials.

Conclusion

In conclusion, lug-type butterfly valves are essential components in modern industrial systems, combining efficiency with reliability. Their unique design offers advantages in terms of space, ease of maintenance, and material adaptability. As industries continue to evolve and demand more efficient systems, the lug-type butterfly valve remains a preferred choice for engineers and operators alike. The ongoing advancements in valve technology will likely enhance the performance and capabilities of these crucial devices, ensuring they continue to play a vital role in fluid control applications for years to come.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025