Rgs . 29, 2024 05:29 Back to list

Versatile Rubber Expansion Joint for Enhanced Flexibility and Performance in Various Applications

Flexible Rubber Expansion Joints Importance and Applications

Flexible rubber expansion joints are essential components in various piping and ducting systems, designed to absorb movement, reduce vibration, and accommodate thermal expansion. These joints are made from high-quality rubber materials, which provide excellent resilience and durability, making them suitable for a wide range of industrial applications.

One of the primary functions of flexible rubber expansion joints is to absorb thermal expansion caused by temperature fluctuations in pipes. When materials like metal heat up, they expand; when they cool down, they contract. This expansion and contraction can lead to stress and potential damage to piping systems. By integrating flexible rubber expansion joints into the design, engineers ensure that the system can accommodate these changes without causing undue stress on the pipes and fittings.

Additionally, flexible rubber expansion joints play a significant role in reducing vibrations and noise in piping systems. Various industrial processes generate vibrations, which can be detrimental to both equipment and personnel. These expansion joints act as a buffer, minimizing the transmission of vibrations through the system, thereby enhancing operational efficiency and comfort. This noise cancellation is particularly crucial in industries such as power generation, water treatment, and HVAC systems, where excessive noise can lead to an uncomfortable work environment.

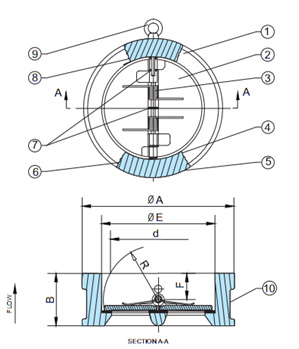

flexible rubber expansion joint

Another major advantage of using flexible rubber expansion joints is their ability to compensate for misalignment. In real-world applications, it is common for pipes to be misaligned due to installation errors or ground settlement. Flexible rubber expansion joints can easily accommodate such misalignments, preventing stresses that could lead to leaks or ruptures in the piping system. This characteristic not only prolongs the life of the piping but also reduces maintenance costs.

When considering the material composition of flexible rubber expansion joints, it’s important to note that several types of rubber can be used, each tailored for specific applications. For instance, EPDM (ethylene propylene diene monomer) is commonly used for water and waste treatment applications due to its excellent resistance to aging and oxidation. Similarly, neoprene is favored for its resistance to oil and chemicals, making it an excellent choice for petroleum-related applications.

Installation of flexible rubber expansion joints is relatively straightforward, making them a preferred choice among engineers and maintenance personnel. They can be installed in various orientations, including horizontal, vertical, or at angles, making them highly versatile. Proper installation is crucial to ensure that they perform optimally, so it is essential to follow manufacturer guidelines during the process.

In summary, flexible rubber expansion joints are indispensable in managing movement, vibration, and misalignment in piping systems across multiple industries. Their ability to absorb thermal expansion, reduce noise, and compensate for installation inconsistencies makes them an invaluable component in ensuring the reliability and longevity of piping infrastructure. With their variety of applications and customizable materials, flexible rubber expansion joints continue to be a pivotal solution in maintaining efficient and effective industrial processes.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025