ມ.ກ. . 11, 2025 10:52 Back to list

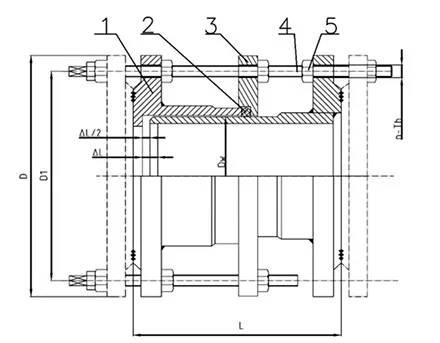

wafer type gate valve

When choosing the ideal gate valve for any application, the socket and resilient seat gate valve stands out due to its superior performance and enduring reliability. For professionals working in water management, municipal projects, or industrial systems, understanding the distinct advantages of these valves can dramatically improve operational efficiency.

The authority of using well-trusted brands is another consideration for businesses aiming to ensure optimal performance. Brands that have established a reputation for quality and have undergone rigorous testing and certification processes are more likely to deliver products that meet or exceed performance expectations. By selecting trusted brands, users can be assured of the valve’s compliance with industry standards. Building trust in using socket and resilient seat gate valves involves not only selecting the right product but also ensuring it’s adequately maintained. Conducting regular inspections and adhering to recommended maintenance schedules prevents operational problems and extends the life of the valve. Service providers who specialize in valve maintenance can offer valuable support, providing expertise that ensures valves operate smoothly for years. Furthermore, adapting to technological advancements within valve manufacturing can enhance the selection and use of socket and resilient seat gate valves. Innovations in materials science and engineering design continuously improve their performance characteristics, offering increased reliability and efficiency. By focusing on experience, expertise, authoritativeness, and trustworthiness, companies can optimize their fluid management systems, ensuring not only efficient operation but also a commitment to quality and reliability. Socket and resilient seat gate valves remain a pivotal component in achieving these operational goals, providing robust solutions tailored to an array of industrial and municipal applications.

The authority of using well-trusted brands is another consideration for businesses aiming to ensure optimal performance. Brands that have established a reputation for quality and have undergone rigorous testing and certification processes are more likely to deliver products that meet or exceed performance expectations. By selecting trusted brands, users can be assured of the valve’s compliance with industry standards. Building trust in using socket and resilient seat gate valves involves not only selecting the right product but also ensuring it’s adequately maintained. Conducting regular inspections and adhering to recommended maintenance schedules prevents operational problems and extends the life of the valve. Service providers who specialize in valve maintenance can offer valuable support, providing expertise that ensures valves operate smoothly for years. Furthermore, adapting to technological advancements within valve manufacturing can enhance the selection and use of socket and resilient seat gate valves. Innovations in materials science and engineering design continuously improve their performance characteristics, offering increased reliability and efficiency. By focusing on experience, expertise, authoritativeness, and trustworthiness, companies can optimize their fluid management systems, ensuring not only efficient operation but also a commitment to quality and reliability. Socket and resilient seat gate valves remain a pivotal component in achieving these operational goals, providing robust solutions tailored to an array of industrial and municipal applications.

Share

Prev:

Next:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025