ພ.ຈ. . 21, 2024 21:44 Back to list

triple offset butterfly valve

Understanding the Triple Offset Butterfly Valve A Comprehensive Overview

The triple offset butterfly valve is an advanced valve design that offers exceptional performance in various industrial applications. Known for its efficiency, durability, and versatility, the triple offset butterfly valve is a solution often chosen for critical applications in industries such as oil and gas, water treatment, and power generation. This article delves into its design, features, advantages, and applications, providing a comprehensive understanding of this vital component in modern engineering.

Design Features

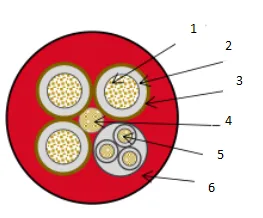

The triple offset butterfly valve is characterized by three key offsets in its design

1. Axis Offset The first offset is between the valve body and the axis of the disc. This means the disc moves away from the valve seat when in the open position, reducing wear and creating less turbulence.

2. Cone Offset The second offset corresponds to the cone shape of the disc. This design feature ensures that the disc does not touch the seat until fully closed, allowing for a tighter seal and reducing the chance of seat damage.

3. Stem Offset The third offset is located at the stem, which is aligned with the valve’s axis. This offset allows for a frictionless sealing process as the valve opens and closes.

These three offsets work together to provide a valve that seals tightly, offers significant flow control, and enhances operational efficiency.

Advantages

The triple offset butterfly valve comes with several advantages that make it a preferred choice in many industries

1. Leakage Control With its unique design, the triple offset butterfly valve provides excellent sealing capabilities. It minimizes the chances of leakage, which is crucial in industries dealing with hazardous materials.

2. Durability and Longevity The materials used in constructing the triple offset butterfly valve are designed to withstand harsh conditions, including extreme temperatures and corrosive environments. This durability translates to a longer operational life and reduced maintenance costs.

triple offset butterfly valve

3. Flow Characteristics These valves allow for a full range of flow characteristics, which means they can effectively regulate the flow of fluids in a system. The unique design reduces turbulence and pressure drops, enhancing system efficiency.

4. Compact Design The compact nature of the triple offset butterfly valve makes it easier to install in tight spaces, which is often a crucial factor in industrial settings.

5. Versatility These valves can handle a variety of fluids, including gases, liquids, and slurries, making them suitable for various applications across multiple industries.

Applications

The versatility of the triple offset butterfly valve lends itself to numerous applications

- Oil and Gas The valve's ability to handle high pressures and corrosive materials makes it suitable for upstream, midstream, and downstream operations in the oil and gas sector.

- Water Treatment In water and wastewater treatment plants, the valves are used for isolation as well as flow control, contributing to efficient resource management.

- Power Generation Triple offset butterfly valves are commonly used in power plants to manage steam and water flows, ensuring safety and efficiency in energy production.

- Chemical Processing Their robust sealing capabilities make them ideal for chemical transport and processing applications.

Conclusion

The triple offset butterfly valve is a crucial component in modern industrial applications due to its unique design and numerous advantages. Its ability to provide tight sealing, durability, and efficient flow control makes it an optimal choice for a wide range of industries—from oil and gas to water treatment and chemical processing. As industries continue to seek greater efficiency and reliability, the triple offset butterfly valve will undoubtedly remain at the forefront of valve technology, adapting to meet the evolving demands of the global market. Understanding its design principles and applications is essential for engineers and industry professionals looking to enhance their systems and processes with technologically advanced solutions.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025