ພ.ຈ. . 21, 2024 03:16 Back to list

di wafer type butterfly valve

Understanding the Di Wafer Type Butterfly Valve A Comprehensive Overview

In the realm of industrial flow control, one component stands out for its efficiency and versatility—the butterfly valve. Specifically, the Di wafer type butterfly valve has garnered attention for its innovative design and functional prowess in various applications. This article delves into the characteristics, applications, advantages, and installation considerations of the Di wafer type butterfly valve.

What is a Di Wafer Type Butterfly Valve?

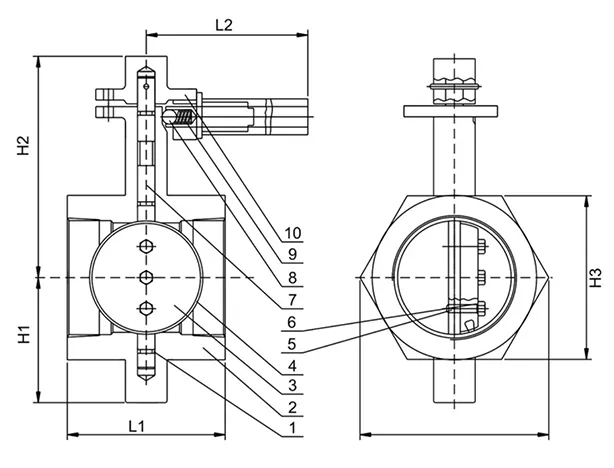

The Di wafer type butterfly valve is a crucial component used to regulate fluid flow in pipelines. The Di in its name typically refers to the ductile iron material commonly used in the valve's construction, which provides enhanced strength and durability. Its design features a circular disc that rotates around an axis within the body of the valve, allowing for quick and efficient opening and closing. The wafer type indicates that the valve is installed between two flanges, making it compact and easy to integrate into existing piping systems.

Key Characteristics

One of the defining characteristics of the Di wafer type butterfly valve is its lightweight construction, which significantly reduces the need for heavy supports. The robust ductile iron material ensures that it can withstand high pressure and temperature variations, making it suitable for various industrial environments. Additionally, the valve often comes with an elastomeric seal, which provides a tight shut-off and minimizes leakage.

Another notable feature is its simple operation. The valve can be actuated manually with a handle or automatically using pneumatic or electric actuators. This feature allows for flexibility in operation, making it suitable for both small-scale and large-scale systems.

Applications

Di wafer type butterfly valves are used across various industries due to their adaptability and reliability

. Common applications includedi wafer type butterfly valve

- Water Treatment Plants These valves are essential for regulating water flow and controlling pressure within the system. - Chemical Processing In the chemical industry, they are used for handling corrosive fluids and gases, ensuring safe and effective processing. - HVAC Systems The compact design of wafer type butterfly valves makes them ideal for heating, ventilation, and air conditioning systems, where space efficiency is critical. - Food and Beverage The sanitary design of specific models makes them suitable for the food and beverage industry, where hygiene and contamination prevention are paramount.

Advantages

The Di wafer type butterfly valve offers several advantages that make it a preferred choice for engineers and facility managers

1. Space Efficiency Its design allows for easy installation in tight spaces without the need for extensive supports, making it ideal for constrained environments. 2. Cost-Effectiveness Compared to other valve types, butterfly valves are generally more economical, both in initial purchase costs and maintenance. 3. Quick Operation The quarter-turn operation ensures rapid opening and closing, providing efficient flow control. 4. Versatile Material Options While ductile iron is common, these valves can also be fabricated from various materials to suit specific operational requirements, including stainless steel, PVC, or carbon steel.

Installation Considerations

When installing a Di wafer type butterfly valve, several considerations should be kept in mind

- Alignment Proper alignment between the valve and the pipe flanges is crucial for ensuring effective sealing and preventing leakage. - Torque Specifications If an actuator is being used, it is essential to adhere to the manufacturer's torque specifications to avoid damage to the valve. - Regular Maintenance Despite their durability, regular checks and maintenance are crucial to extend the valve's lifespan and ensure optimal performance.

Conclusion

The Di wafer type butterfly valve is a versatile and efficient solution for various flow control applications. Its robust design, space-saving features, and cost-effectiveness make it a popular choice across numerous industries. Understanding its characteristics and proper installation practices can significantly enhance operational efficiency and system reliability, making it an invaluable component in modern industrial processes. As industries continue to evolve, the role of innovative components like the Di wafer type butterfly valve will remain critical in meeting the demands of increased efficiency and performance.

Share