Dec . 01, 2024 04:03 Back to list

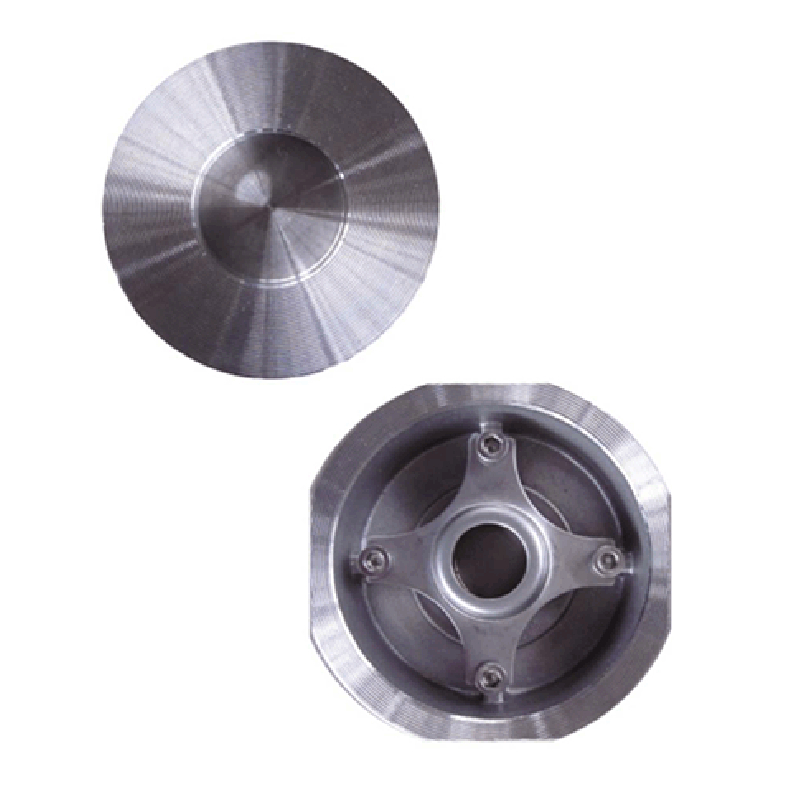

wafer type butterfly check valve

Understanding the Wafer Type Butterfly Check Valve A Fundamental Component in Fluid Systems

In industrial applications, the selection of appropriate valves plays a critical role in ensuring efficient fluid control and system integrity. Among the various types of valves available, the wafer type butterfly check valve stands out as an effective solution for preventing backflow in piping systems. Its design and functionality cater to a wide range of industries, from water treatment to oil and gas, making it essential for engineers and designers to understand its characteristics and advantages.

What is a Wafer Type Butterfly Check Valve?

A wafer type butterfly check valve is a compact, lightweight valve that operates on the principle of a rotating disc. The 'wafer' design allows the valve to be sandwiched between two flanges, which simplifies installation and maintenance. Unlike traditional check valves that might have bulky structures, the wafer butterfly check valve is characterized by its streamlined profile, minimizing pressure loss and ensuring smooth fluid flow.

Working Mechanism

The butterfly check valve's operation hinges on a disc that pivots around a central shaft. When fluid flows in the designated direction, the disc opens, allowing the medium to pass through. Should there be a reverse flow, the disc swings back against the valve seat, effectively blocking the backward movement. This mechanism prevents backflow, which can lead to contamination and damage in various systems. Additionally, its quick-acting nature helps maintain the system's efficiency, making it ideal for dynamic applications where fluid direction can rapidly change.

Advantages of Wafer Type Butterfly Check Valves

wafer type butterfly check valve

1. Space Efficiency The wafer design requires less space compared to conventional valves, making it suitable for installations where space is limited. This is particularly beneficial in crowded industrial environments or where piping configurations are complex.

2. Reduced Weight The lightweight construction of wafer type butterfly check valves simplifies handling and installation, reducing the overall installation costs and labor efforts.

3. Low Pressure Drop These valves are designed to minimize pressure loss during operation. The streamlined disc and compact design ensure that flow resistance is kept to a minimum, contributing to energy efficiency throughout the system.

4. Versatility Wafer type butterfly check valves are suitable for a wide range of applications, including water, oil, and gas. Their ability to handle harsh conditions makes them a preferred choice in many sectors, such as chemical processing, power generation, and HVAC systems.

5. Cost-Effectiveness Compared to other check valve designs, wafer type butterfly check valves often present a more economical solution, combining performance with affordability.

Conclusion

In conclusion, the wafer type butterfly check valve is an integral component in modern fluid control systems. Its unique design, efficient operation, and numerous advantages make it a popular choice across various industries. Whether it’s for preventing backflow in water treatment facilities or ensuring safety in oil and gas pipelines, understanding the functionalities and benefits of these valves is crucial for anyone involved in fluid system design and maintenance. Embracing this knowledge not only aids in selecting the right components but also enhances the overall efficiency and reliability of industrial applications.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025