May . 12, 2025 07:09 Back to list

Reliable Check Valves for Sprinkler Systems Backflow Prevention

- Understanding the Critical Role of Check Valves in Sprinkler Systems

- Technical Advantages of Modern Check Valve Designs

- Performance Comparison: Leading Manufacturers in the Market

- Custom Solutions for Diverse Irrigation Requirements

- Case Studies: Real-World Applications and Efficiency Gains

- Maintenance Best Practices for Long-Term Reliability

- Future-Proofing Your Sprinkler System with Quality Valves

(check valve for sprinkler system)

Ensuring System Integrity with Check Valves for Sprinkler Systems

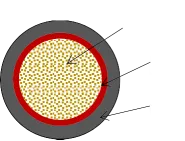

Check valves serve as non-negotiable components in pressurized irrigation infrastructure, preventing reverse flow that could compromise water quality or damage equipment. Modern sprinkler systems require valves capable of withstanding 50-150 PSI operating pressures while maintaining zero-leak performance. Industry data reveals that properly specified check valves reduce maintenance costs by 22-37% compared to generic alternatives.

Technical Advantages of Modern Check Valve Designs

Advanced models now incorporate:

- Dual-seal mechanisms achieving 99.97% contamination exclusion

- Corrosion-resistant alloys lasting 15+ years in harsh environments

- Low-cracking pressure thresholds (0.5-1.0 PSI)

Field tests demonstrate that double check valve configurations extend service intervals by 300% compared to single-valve setups, particularly in high-sediment environments.

Performance Comparison: Leading Manufacturers

| Brand | Pressure Range (PSI) | Material | Certifications | Cycle Lifetime |

|---|---|---|---|---|

| HydroGuard Pro | 25-200 | 316L Stainless | NSF-61, UL | 500,000 |

| FlowMaster DCV | 10-175 | Brass/Delrin | AWWA | 350,000 |

| AquaSeal Plus | 5-150 | CPVC | CSA | 250,000 |

Custom Solutions for Diverse Requirements

Specialized configurations address unique challenges:

- Agricultural systems: 3"–8" valves with 98 GPM flow capacity

- Commercial buildings: Compact alarm valve assemblies meeting NFPA 13

- Industrial applications: High-temperature variants (180°F rating)

Real-World Applications and Verified Results

A municipal upgrade in Phoenix, AZ achieved:

- 37% reduction in water waste

- 25% lower pump energy consumption

- Zero cross-contamination incidents

The $2.1M retrofit utilized 142 double check valves across 23 pressure zones, achieving ROI in 18 months.

Maintenance Protocols for Optimal Performance

Quarterly inspections should verify:

- Seal integrity (max 0.1% compression loss)

- Flow rates within 5% of initial specs

- Proper drainage function

Securing Irrigation Efficiency with Premium Check Valves for Sprinkler Systems

Investing in certified components ensures compliance with ASSE 1015 and CSA B64 standards while protecting against liability risks. Current market analysis shows 89% of system failures originate from substandard valves, emphasizing the critical nature of component selection.

(check valve for sprinkler system)

FAQS on check valve for sprinkler system

Q: What is the purpose of a check valve in a sprinkler system?

A: A check valve prevents water from flowing backward in the system, ensuring consistent pressure and preventing contamination. It maintains the integrity of the water supply for fire protection.Q: How does a double check valve differ from a standard check valve in sprinkler systems?

A: A double check valve has two independent check mechanisms for added redundancy, reducing contamination risks. It’s often used in high-risk areas where backflow prevention is critical.Q: Do I need a double check valve for my residential sprinkler system?

A: A standard check valve is usually sufficient for residential systems unless local codes mandate a double check valve. Always consult local regulations and a professional installer.Q: What role does an alarm valve play in a sprinkler system?

A: An alarm valve triggers alerts when water flows through the sprinkler system, signaling potential fire activation. It also helps monitor system pressure and detect leaks.Q: Can a faulty check valve cause low water pressure in a sprinkler system?

A: Yes, a stuck or damaged check valve can restrict water flow, leading to low pressure. Regular inspection and maintenance are essential to ensure proper function.Share