Dec . 01, 2024 06:21 Back to list

MSS standard metal seated gate valve for reliable sealing and performance

MSS Metal Seat Gate Valves A Comprehensive Overview

Gate valves are essential components in various industrial systems, particularly in managing the flow of liquids and gases. They work by using a gate mechanism to control fluid flow, providing a significant advantage in applications where minimal pressure drop and tight sealing are critical. Among the various types of gate valves, the MSS (Manufacturers Standardization Society) metal seat gate valves stand out due to their robust design and reliability in demanding environments.

Overview of MSS Metal Seat Gate Valves

MSS metal seat gate valves are designed to operate under harsh conditions while maintaining the utmost efficiency. They utilize a metal-to-metal seating surface, which offers several advantages compared to softer materials such as rubber or plastic. The metal seat design enhances durability and provides a better performance in high-temperature and high-pressure applications. This makes them suitable for industries such as oil and gas, petrochemical, power generation, and water treatment.

Key Features and Specifications

1. Material Composition Typically, MSS metal seat gate valves are made from high-quality materials like stainless steel, carbon steel, or alloy materials. The choice of material heavily depends on the application conditions, including temperature, pressure, and the nature of the fluid being transported.

2. Construction Standards The MSS has established standards that govern the design, manufacturing, and testing of metal seat gate valves. These standards ensure consistent quality and performance across different manufacturers, making it easier for engineers to select the appropriate valve based on their specific needs.

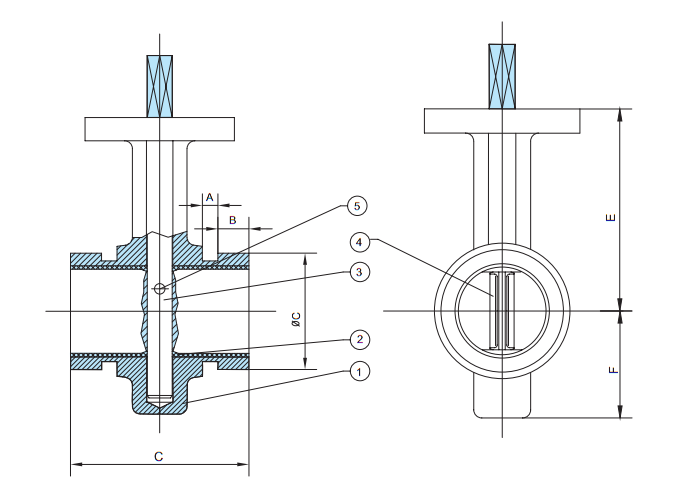

3. Design Configurations These valves come in various configurations, including rising stem and non-rising stem designs. In a rising stem design, the stem rises with the valve, providing a visual indication of the valve’s position. Non-rising stems, on the other hand, are utilized where vertical space is limited.

4. Pressure and Temperature Ratings MSS metal seat gate valves are available in a range of pressure and temperature ratings, enabling their use in a wide array of applications. Engineers should carefully consider these specifications when selecting a valve for their system to ensure optimal performance.

5. Sealing Performance One of the primary advantages of metal seat gates is their enhanced sealing capabilities. The metal-to-metal seating ensures a tight seal, preventing leakage and allowing for the safe transport of hazardous fluids.

mss metal seat gate valve

Applications of MSS Metal Seat Gate Valves

MSS metal seat gate valves are versatile and commonly used across numerous industries. Some significant applications include

- Oil and Gas In upstream and downstream operations, these valves control the flow of crude oil and natural gas, providing a robust solution for demanding environments. - Chemical Processing The ability to handle corrosive and high-temperature fluids makes MSS metal seat gate valves an ideal choice in the chemical industry, where safety and reliability are paramount.

- Power Generation These valves are instrumental in steam and water control systems within power plants, ensuring efficient energy production.

- Water Treatment In municipal water systems, the valves aid in the regulation of water flow, contributing to effective treatment and distribution.

Maintenance and Longevity

Like any industrial component, proper maintenance is crucial for the longevity and performance of MSS metal seat gate valves. Regular inspections should be conducted to check for signs of wear, corrosion, or leakage. Lubrication of moving parts can help ensure smooth operation. It is also essential to follow the manufacturer's guidelines for installation and operation to prevent premature failure.

Conclusion

MSS metal seat gate valves play a pivotal role in a variety of industries, providing reliable flow control solutions that can withstand rigorous demands. Their robust design, combined with stringent manufacturing standards, ensures that they meet the needs of today's complex systems. As industries continue to evolve, the importance of these valves will only increase, making them a critical component in modern infrastructure. Whether for oil and gas applications or chemical processing, understanding the features and advantages of metal seat gate valves is essential for engineers and decision-makers in selecting the right valve for their specific applications.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025