Feb . 15, 2025 21:25 Back to list

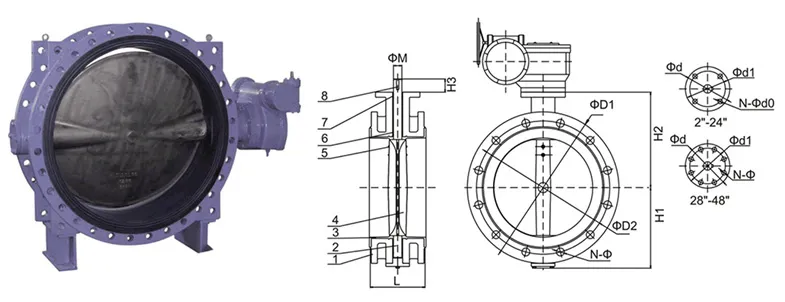

flange type butterfly valve

The burgeoning world of industrial mechanics and fluid control systems is witnessing an increasingly indispensable component the butterfly valve with actuator. This marvel of engineering seamlessly combines precision with functionality, marking a revolution in fluid control applications across numerous industries. Understanding its role and numerous advantages offers valuable insights for both the seasoned engineer and the novice exploring modern industrial efficiencies.

In terms of authoritativeness, the adoption of butterfly valves with actuators is endorsed by leading industry standards such as the American Petroleum Institute (API) and the International Organization for Standardization (ISO). These endorsements cement the credibility and reliability of these systems, ensuring they meet stringent quality and performance benchmarks. Industries relying on these components can trust their compliance with international safety and efficiency standards, which is particularly crucial in global operations. Trustworthiness is further bolstered by documented case studies and real-world applications demonstrating the performance and reliability of butterfly valves with actuators. In water treatment plants, for instance, these systems have been shown to improve water flow management significantly, enhancing the treatment process's efficiency and reducing waste. Additionally, in the oil and gas industry, they are frequently used to manage varying pressure levels and flow conditions, proving their versatility and resilience under challenging conditions. Maintenance and versatility are other critical aspects where these devices excel. Regular maintenance of butterfly valves with actuators is straightforward, thanks to their simple design and robust construction. The components can be easily accessed for inspection and repairs, which minimizes downtime and ensures continued operation. Furthermore, their design adaptability allows for use in various system configurations, enabling seamless integration with existing infrastructures. In conclusion, the butterfly valve with actuator is more than just a product; it embodies a significant leap forward in industrial process control. Its integration into systems delivers exceptional control, efficiency, and safety, while its recognition by prominent industry authorities assures its reliability. As industries continuously seek scalable and sustainable solutions, the butterfly valve with actuator presents itself as an indispensable component in the future of fluid dynamics and industrial operations. Whether you're seeking enhanced precision in fluid control, reduced operational risk, or alignment with industry standards, this technology offers a comprehensive solution equipped to meet the challenges of contemporary industrial demands.

In terms of authoritativeness, the adoption of butterfly valves with actuators is endorsed by leading industry standards such as the American Petroleum Institute (API) and the International Organization for Standardization (ISO). These endorsements cement the credibility and reliability of these systems, ensuring they meet stringent quality and performance benchmarks. Industries relying on these components can trust their compliance with international safety and efficiency standards, which is particularly crucial in global operations. Trustworthiness is further bolstered by documented case studies and real-world applications demonstrating the performance and reliability of butterfly valves with actuators. In water treatment plants, for instance, these systems have been shown to improve water flow management significantly, enhancing the treatment process's efficiency and reducing waste. Additionally, in the oil and gas industry, they are frequently used to manage varying pressure levels and flow conditions, proving their versatility and resilience under challenging conditions. Maintenance and versatility are other critical aspects where these devices excel. Regular maintenance of butterfly valves with actuators is straightforward, thanks to their simple design and robust construction. The components can be easily accessed for inspection and repairs, which minimizes downtime and ensures continued operation. Furthermore, their design adaptability allows for use in various system configurations, enabling seamless integration with existing infrastructures. In conclusion, the butterfly valve with actuator is more than just a product; it embodies a significant leap forward in industrial process control. Its integration into systems delivers exceptional control, efficiency, and safety, while its recognition by prominent industry authorities assures its reliability. As industries continuously seek scalable and sustainable solutions, the butterfly valve with actuator presents itself as an indispensable component in the future of fluid dynamics and industrial operations. Whether you're seeking enhanced precision in fluid control, reduced operational risk, or alignment with industry standards, this technology offers a comprehensive solution equipped to meet the challenges of contemporary industrial demands.

Share

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025