Aug . 27, 2024 15:38 Back to list

High-Quality Ball Valves for Optimal Flow Control

Understanding Ball Valves Essential Components in Fluid Control

Ball valves are critical components in various industries, utilized for controlling the flow of liquids and gases in piping systems. Their simple yet effective design allows for reliable operation and long service life, making them a popular choice in both residential and industrial settings.

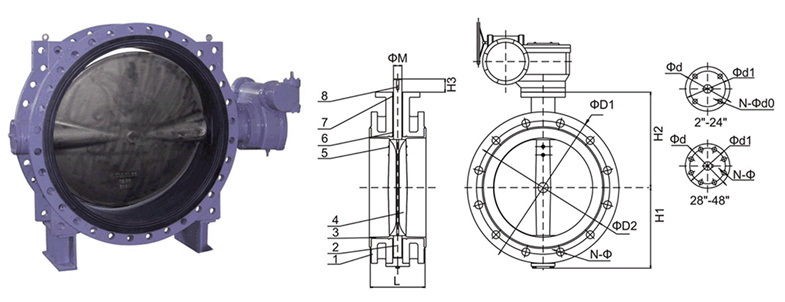

A ball valve consists of a hollow, perforated sphere (the ball) that rotates within a valve body. When the ball's hole is aligned with the flow direction, the valve is open, allowing fluid to pass through. Conversely, when the ball is turned 90 degrees, the flow is blocked, effectively closing the valve. This quarter-turn operation is one of the reasons ball valves are favored, as they provide quick and easy flow control.

One of the notable advantages of ball valves is their tight sealing capability. When closed, the ball seals against the valve seat, which minimizes leakage and ensures that fluids do not pass through when the valve is not in use. This trait is particularly important in applications requiring high-pressure systems or hazardous materials. Additionally, ball valves can handle a wide range of temperatures, making them suitable for diverse environments.

In terms of construction, ball valves can be made from various materials, including stainless steel, brass, and plastic

. The choice of material often depends on the fluid being controlled and the conditions of use. For instance, stainless steel ball valves are commonly used in corrosive environments, while plastic valves may be ideal for less demanding applications.ball valve

The design also includes different types of end connections, such as threaded, flanged, and welded. This versatility allows ball valves to be integrated seamlessly into existing systems, enhancing their appeal for engineers and designers. Furthermore, the compact design of ball valves saves space, making them suitable for installations where room is limited.

Maintenance of ball valves is relatively straightforward. Regular inspection can ensure they remain operational and minimize the risk of failure. In most cases, a simple visual check or the use of a diagnostic tool can help identify any issues before they escalate.

In recent years, advancements in technology have led to the development of automated ball valves. These electronically operated valves can be controlled remotely, allowing for precise flow regulation and enhanced system efficiency. As industries continue to evolve towards automation, ball valves will likely play a vital role in modern fluid control systems.

In conclusion, ball valves are essential for ensuring efficient and reliable fluid management across numerous applications. Their durability, tight sealing capabilities, and ease of use make them a preferred option for engineers and operators alike. Whether in residential plumbing, commercial facilities, or complex industrial processes, understanding the function and advantages of ball valves is crucial for anyone involved in fluid control systems.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025