کانونی یەکەم . 20, 2024 23:35 Back to list

teflon butterfly valve

Teflon Butterfly Valves An Overview of Their Design and Applications

In the world of industrial applications, the efficiency and reliability of valve systems are paramount. One particular type of valve that has garnered attention for its performance capabilities is the butterfly valve, specifically those lined or coated with Teflon. This article delves into the unique properties of Teflon butterfly valves, their design features, advantages, and common applications.

Understanding Butterfly Valves

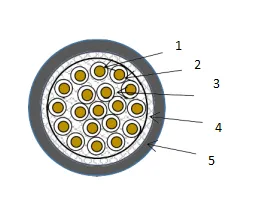

Butterfly valves are quarter-turn rotational valves that regulate flow. They consist of a disc that rotates around a central shaft, allowing fluid to pass when the disc is parallel to the flow and stopping it when the disc is perpendicular. This simple yet effective design makes butterfly valves compact and lightweight compared to other valve types.

The Role of Teflon

Teflon, known scientifically as polytetrafluoroethylene (PTFE), is a high-performance plastic that exhibits exceptional chemical resistance and low friction. This makes it particularly suitable for environments that deal with corrosive fluids or require a low friction coefficient for ease of operation. When integrated into butterfly valves, Teflon can be used as a liner or as a coating, enhancing the valve's lifespan and overall functionality.

Design Features

Teflon butterfly valves are designed with various features that cater to specific industrial needs

1. Sealing Mechanism The use of Teflon significantly improves the sealing capabilities of the valve. The material's resilience ensures a tight seal, minimizing the risk of leaks and enhancing the valve's overall performance.

2. Corrosion Resistance One of the most compelling advantages of Teflon butterfly valves is their resistance to corrosive substances. Industries such as chemical processing, wastewater treatment, and food and beverage can greatly benefit from this feature, as it reduces maintenance costs and improves system reliability.

3. Temperature Resistance Teflon can withstand a wide range of temperatures. This quality allows Teflon butterfly valves to be used in both high-temperature and low-temperature applications, making them versatile for various industrial processes.

teflon butterfly valve

4. Lower Maintenance The low coefficient of friction of Teflon means that these valves experience less wear and tear over time. This aspect leads to reduced maintenance requirements and longer service life, translating into cost savings for businesses.

Advantages of Teflon Butterfly Valves

1. Versatility Teflon butterfly valves can handle a variety of fluids, ranging from water to aggressive chemicals. Their adaptability makes them suitable for numerous applications across different sectors.

2. Energy Efficiency The efficient design of butterfly valves, combined with the low friction of Teflon, ensures that less energy is required to operate the valve. This can lead to overall energy savings for industrial operations.

3. Ease of Installation Teflon butterfly valves are generally lighter than traditional valves, making them easier to install and handle. Their compact design facilitates integration into existing systems without requiring significant modifications.

4. Cost-effective Solutions Although the initial cost of Teflon butterfly valves may be higher than some other types, their longevity and reduced maintenance needs make them a cost-effective solution in the long run.

Common Applications

Teflon butterfly valves find their place in many industrial applications such as

- Chemical Processing Due to their resistance to corrosive materials, these valves are ideal for controlling the flow of acids, bases, and solvents. - Water Treatment Their durability and ease of use make them popular in wastewater treatment plants and in potable water systems. - Food and Beverage Industry The non-toxic properties of Teflon make these valves suitable for food processing, ensuring compliance with safety standards. - Pharmaceuticals The high purity and chemical resistance of Teflon butterfly valves make them a preferred choice in pharmaceutical manufacturing.

Conclusion

Teflon butterfly valves represent a fusion of innovative materials and efficient design, making them a key component in many industrial processes. Their unique properties provide numerous advantages, including corrosion resistance, temperature tolerance, and reduced maintenance. As industries continue to evolve, the demand for reliable and efficient valve solutions will only grow, positioning Teflon butterfly valves as a significant player in the landscape of industrial equipment.

Share