تشرینی دووەم . 14, 2024 13:15 Back to list

di lug type butterfly valve

Understanding Di Lug Type Butterfly Valves

Butterfly valves are a crucial component in various industrial applications, serving as regulation mechanisms for controlling fluid flow. Among the different types of butterfly valves, the dual lug or di lug type is noteworthy for its unique design and functionality. This article aims to provide an overview of di lug type butterfly valves, highlighting their structure, advantages, applications, and maintenance considerations.

Design Characteristics

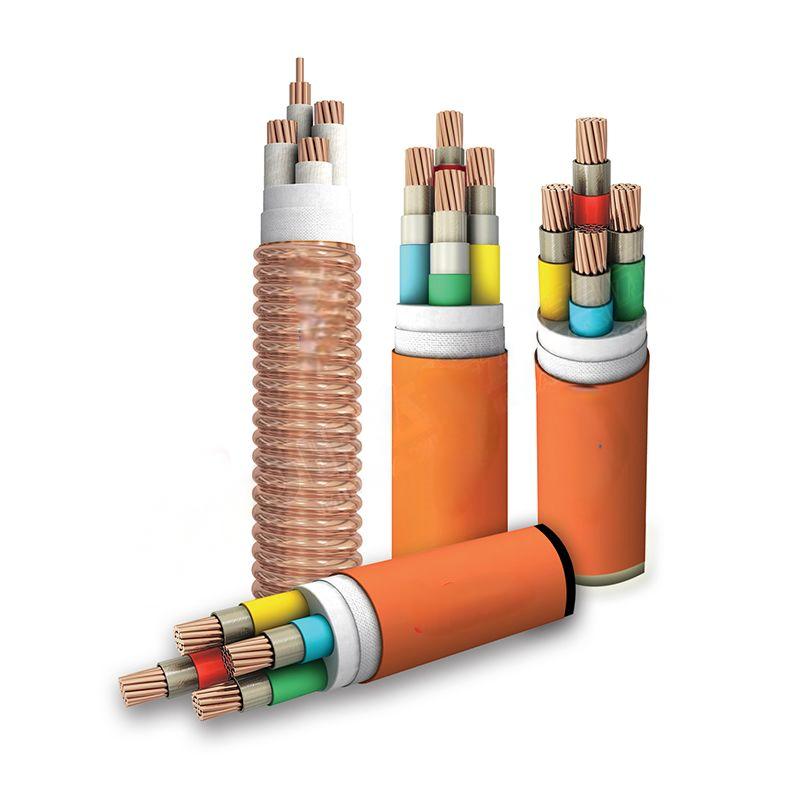

The di lug type butterfly valve features two lugs attached to the valve body on either side, ensuring a secure and stable installation. This design allows for easy mounting between flanges, making it suitable for a variety of piping systems. The valve consists of a disc that rotates around a central axis, which is positioned in the flow path. When the valve is closed, the disc blocks the flow, while turning it to an open position permits fluid to flow through.

These valves are available in different materials, including cast iron, stainless steel, and plastic, enabling them to handle various media types from water to aggressive chemicals. The di lug configuration is particularly advantageous in high-pressure systems where a reliable sealing mechanism is paramount.

Advantages

One of the significant benefits of di lug type butterfly valves is their compact design. Unlike gate or globe valves, which can be bulky, butterfly valves occupy minimal space, making them ideal for installations with space constraints. Their lightweight nature also simplifies installation, reducing the labor and time required for setup.

Another advantage is their quick operation. The disc can be fully opened or closed with just a quarter turn of the handle, allowing for efficient control of fluid flow. This quick actuating capability is especially beneficial in applications requiring rapid response to pressure changes.

di lug type butterfly valve

Moreover, di lug type butterfly valves are known for their cost-effectiveness. They typically have lower manufacturing and maintenance costs compared to other valve types. This economic benefit makes them a popular choice in various industries, including water treatment, chemical processing, and HVAC systems.

Applications

Di lug type butterfly valves are versatile and find use in numerous applications. They are widely utilized in water supply and wastewater management systems, where controlling the flow is critical for operational efficiency. Additionally, these valves are commonly found in chemical processing plants, where they regulate the flow of corrosive liquids.

In HVAC systems, di lug butterfly valves play a pivotal role in managing air and fluid flow, contributing to energy efficiency in heating and cooling processes. Their ability to provide tight sealing also makes them suitable for pharmaceuticals, food processing, and other sensitive applications where contamination must be avoided.

Maintenance Considerations

While di lug type butterfly valves are generally low-maintenance, regular inspections are essential to ensure optimal performance. Operators should routinely check for leaks, inspect the seal condition, and verify the proper functioning of the actuator. Lubricating the moving parts can further enhance their lifespan and reliability.

In conclusion, di lug type butterfly valves offer an efficient, space-saving, and cost-effective solution for controlling fluid flow across various industries. Their unique design and operational advantages make them a preferred choice for engineers and facility managers looking to optimize fluid management systems. Proper maintenance and inspection can ensure these valves function effectively, supporting the overall efficiency of industrial operations.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025