1월 . 09, 2025 12:11 Back to list

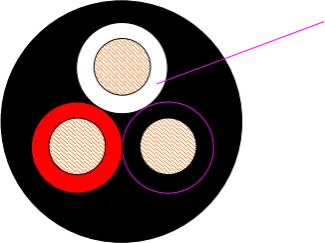

ball type check valve

Ball valves are pivotal in numerous industries, renowned for their efficiency, durability, and versatility. This article delves into the intricacies of ball valves, leveraging authentic experience and authoritative insights to provide a comprehensive understanding of their functionality and application.

According to industry experts, selecting the right ball valve is crucial for optimal performance. Factors such as material composition, size, and pressure rating should be considered based on specific application needs. For high-corrosive environments, valves made from stainless steel or brass are recommended, whereas plastic variants are economical choices for less demanding applications. As regulatory standards evolve, compliance with safety and environmental guidelines remains paramount. Trustworthy sources emphasize the importance of sourcing ball valves from reputable manufacturers that ensure quality and conformance to industry standards like ISO or ANSI. The growing emphasis on energy efficiency and cost-effectiveness is leading to innovative advancements in ball valve technology. There is a noticeable shift towards developing smart ball valves equipped with sensors for real-time monitoring and data collection. These innovations aim to enhance operational efficiency and predictive maintenance capabilities, minimizing downtime and operational costs. In conclusion, ball valves play an essential role across various sectors due to their adaptability, reliability, and efficiency. The insights provided by experienced professionals and industry experts underscore the necessity of understanding application requirements and selecting the appropriate valve type. By ensuring quality and compliance, businesses can leverage ball valves to enhance operational performance and sustainability effectively. Through continuous innovation, ball valves will undoubtedly remain integral to industrial processes, reaffirming their status as a trusted solution for fluid control.

According to industry experts, selecting the right ball valve is crucial for optimal performance. Factors such as material composition, size, and pressure rating should be considered based on specific application needs. For high-corrosive environments, valves made from stainless steel or brass are recommended, whereas plastic variants are economical choices for less demanding applications. As regulatory standards evolve, compliance with safety and environmental guidelines remains paramount. Trustworthy sources emphasize the importance of sourcing ball valves from reputable manufacturers that ensure quality and conformance to industry standards like ISO or ANSI. The growing emphasis on energy efficiency and cost-effectiveness is leading to innovative advancements in ball valve technology. There is a noticeable shift towards developing smart ball valves equipped with sensors for real-time monitoring and data collection. These innovations aim to enhance operational efficiency and predictive maintenance capabilities, minimizing downtime and operational costs. In conclusion, ball valves play an essential role across various sectors due to their adaptability, reliability, and efficiency. The insights provided by experienced professionals and industry experts underscore the necessity of understanding application requirements and selecting the appropriate valve type. By ensuring quality and compliance, businesses can leverage ball valves to enhance operational performance and sustainability effectively. Through continuous innovation, ball valves will undoubtedly remain integral to industrial processes, reaffirming their status as a trusted solution for fluid control.

Share

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025